-

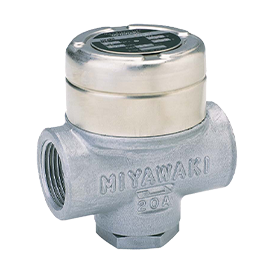

E Series | Inverted Bucket Steam Traps

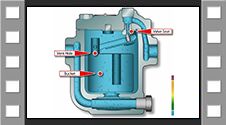

This type of steam trap utilizes the difference in density between steam and condensate, and uses the buoyancy of an open float that takes the form of a bucket to open and close a valve. Miyawaki inverted steam traps include the low-discharge ES Series and the high-discharge ER Series. Both the series use Miyawaki’s SCCV System* for the valve, which offers superb durability and valve closing performance. In addition, ER Series products use a differential pressure double valve system to achieve high discharge, which allows them to discharge the same volume while being much smaller in comparison to other companies’ inverted bucket traps.

-

*SCCV (Self Closing and Centering Valve) System

The valve holder is held in place by a lever, and the valve itself is placed in the small space inside the holder where it is free to move. This design moderates the mechanical force to which is transferred via the lever.

-

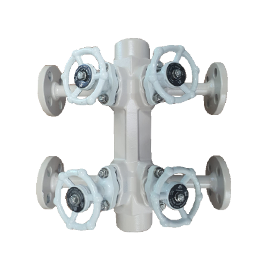

G Series | Ball Float Steam Traps

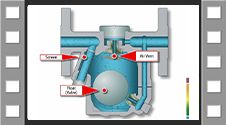

This type of steam trap utilizes the difference in density between steam and condensate, and uses the buoyancy of an airtight ball-shaped float to open and close a valve.

Steam traps that use floats include those with a mechanism in which the force from the buoyancy of the float is transferred to the valve via a lever (lever-float steam traps) and those in which the float itself simultaneously works as a valve without a lever mechanism (lever-free steam traps). Some lever float steam traps use a double ported balance valve system* that enables a high discharge to be achieved by a small unit.-

*Double ported balance valve system

This system maintains a state of equilibrium by two balanced valves subject to pressure pushing against each other. The valves can thus be opened or closed with only a small amount of force, meaning a large quantity of condensate can be discharged with a small float.

-

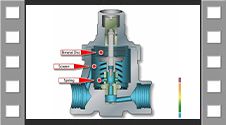

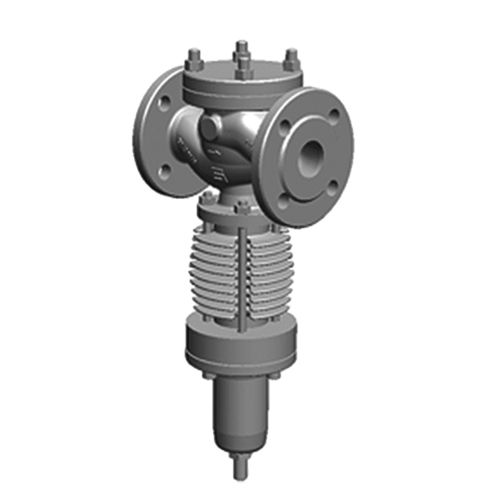

TB Series | Temperature Control Steam Trap

This type of steam trap utilizes the difference in temperature between steam and condensate, and uses the expansion and contraction capacity of a thermosensitive body to open and close a valve. Temperature control steam traps are thermostatic traps that enable the temperature at which they operate to be freely set in advance, and which Miyawaki led the world in the development of as an energy saving trap for steam tracing use.

With a high reliability backed up by a proven track record, these steam traps have been adopted by a wide variety of industries around the world. They are comprised of sturdy internal components that can withstand pressure and shocks, and can also handle the demands placed on steam traps for main steam pipes that contain high-pressure areas and superheated steam.

Uses

Temperature control traps are used to maintain the temperature in steam trace lines and process condensate in main steam pipes. Miyawaki offers a variety of temperature control traps to deal with different pressure areas, ranging from low pressure to extra-high pressure areas.

-

D Series | Diaphragm Steam Traps

Temperature difference between steam and condensate

Diaphragm steam traps are based on a thermoelement (diathermo) that changes shape in response to temperature.

Miyawaki’s D Series diaphragm traps include many stainless steel products with superb anti-corrosion properties, and they have been kept as small as possible to enable them to be installed in tight spaces. The DV1 also has a built-in bypass valve which renders a separate bypass pipe unnecessary, enabling a large reduction in product and pipe installation costs.

There are two types; one with a thermoelement operating temperature 5℃ lower than the saturation temperature, and one with a thermoelement operating temperature 15℃ lower than the saturation temperature.

-

W Series | Thermoelement Steam Traps

This type of steam trap utilizes the expansion and contraction of wax caused by the temperature difference between steam and condensate to open and close a valve.

Uses

These steam traps are suitable low pressure, small scale systems such as heating radiators.

-

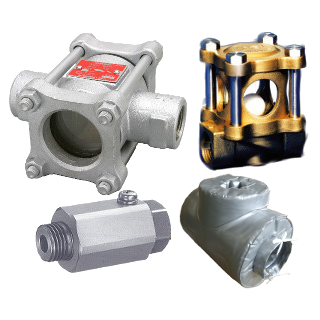

S Series | Thermodynamic Disc Steam Traps

This type of steam trap utilizes the hydrodynamic properties that occur due to differences in the flow velocity between steam and condensate and thermodynamic properties to open and close a valve.

Disk traps have no limitations in terms of installation orientation, making them very easy to use.

The SV1 has a built-in bypass valve which means no bypass pipe is required, thus enabling savings in terms of piping materials and a large reduction in the time required for installation work.

-

Steam Traps with Two-Bolt Connection

All models are made of stainless steel body and stainless steel internals.

They can be installed either horizontally or vertically. Two-bolt connection for simplified replacement of the steam trap.