Ball Float Traps

Air Traps Ball Float Traps

AGH29

Can be used for gas pipings

Features/Applications

Features

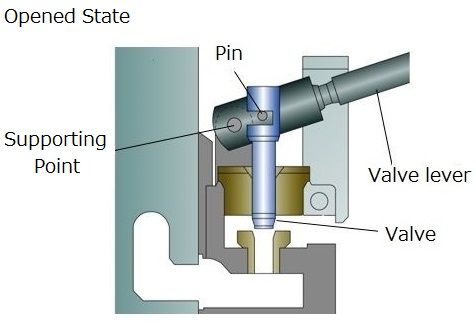

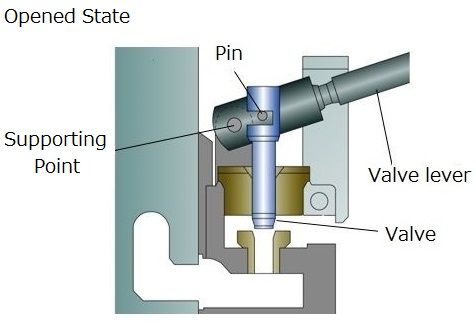

Superb sealing and durability

Offers superb sealing and durability thanks to the MIYAWAKI SCCV System. This valve mechanism was developed by MIYAWAKI to increase valve durability and ensure maximum sealing performance.

Easy maintenance

All units are attached to the cover, making maintenance easy.

*’SCCV System’ is an abbreviation for Self Closing and Centering Valve System and internationally patent.

Typical applications

Suitable for air pipings, aftercoolers, receiver tanks, gas pipimgs, and other such applications.

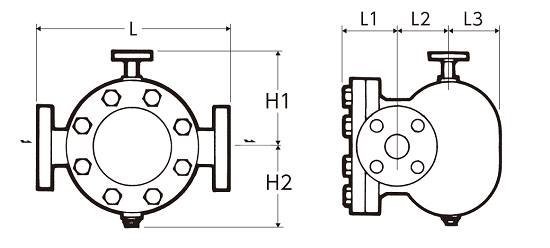

Dimensions/Weight

Dimensions/Weight

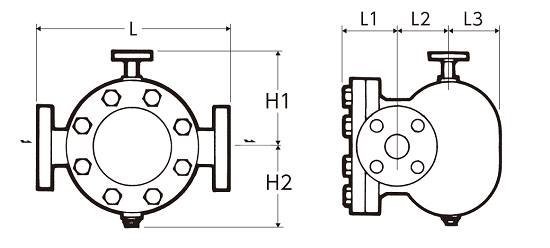

Flanged

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||||||

| L | L1 | L2 | L3 | H1 | H2 | L | L1 | L2 | L3 | H1 | H2 | (kg) | (lb) | |

| 1/2” | 340 | 95 | 80 | 85 | 200 | 120 | 13.4 | 3.7 | 3.1 | 3.3 | 7.9 | 4.7 | 28,0 | 61.6 |

| 3/4” | ||||||||||||||

| 1” | ||||||||||||||

| 1 1/4” | 390 | 15.4 | 32,0 | 70.4 | ||||||||||

| 1 1/2” | ||||||||||||||

| 2” | ||||||||||||||

*Available flange standards: ASME/JPI, DIN, JIS

*Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

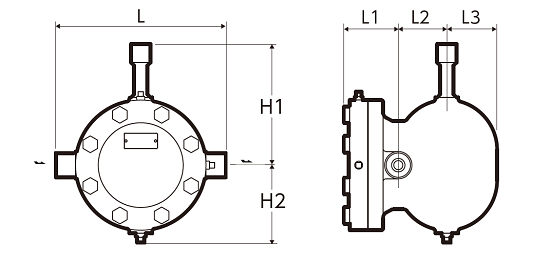

Socket Weld

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||||||

| L | L1 | L2 | L3 | H1 | H2 | L | L1 | L2 | L3 | H1 | H2 | (kg) | (lb) | |

| 1/2” | 280 | 95 | 80 | 85 | 200 | 120 | 11.0 | 3.7 | 3.1 | 3.3 | 7.9 | 4.7 | 25,5 | 56.1 |

| 3/4” | ||||||||||||||

| 1” | ||||||||||||||

Specifications

| Model | Connection |

Max. operating pressure |

Max. operating pressure differential |

Max. operating temperature |

Body material |

||||

| Type | Size | PMO(MPa) | PMO(psig) | ⊿PMX(MPa) | ⊿PMX(psig) | TMO(℃) | TMO(℉) | ||

| AGH29-16 |

Flanged* FF,RF |

1/2” | 3,0 | 435 | 1,6 | 232 | 400 | 752 |

Cast steel WCB |

| 3/4” | |||||||||

| 1” | |||||||||

| 1 1/4” | |||||||||

| 1 1/2” | |||||||||

| 2” | |||||||||

| AGH29-40 | 1/2” | 4,5 | 652 | 4,0 | 580 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

| 1 1/4” | |||||||||

| 1 1/2” | |||||||||

| 2” | |||||||||

| AGH29W-16 |

Socket Weld SW |

1/2” | 3,0 | 435 | 1,6 | 232 | 400 | 752 |

Cast steel WCB |

| 3/4” | |||||||||

| 1” | |||||||||

| AGH29W-40 | 1/2” | 4,5 | 652 | 4,0 | 580 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

*Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

Discharge Capacity

Download

* Membership registration is required to download the documents.

Features

Superb sealing and durability

Offers superb sealing and durability thanks to the MIYAWAKI SCCV System. This valve mechanism was developed by MIYAWAKI to increase valve durability and ensure maximum sealing performance.

Easy maintenance

All units are attached to the cover, making maintenance easy.

*’SCCV System’ is an abbreviation for Self Closing and Centering Valve System and internationally patent.

Typical applications

Suitable for air pipings, aftercoolers, receiver tanks, gas pipimgs, and other such applications.

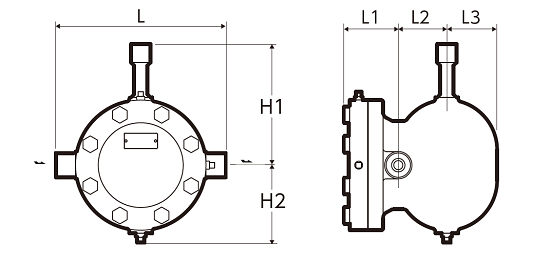

Dimensions/Weight

Flanged

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||||||

| L | L1 | L2 | L3 | H1 | H2 | L | L1 | L2 | L3 | H1 | H2 | (kg) | (lb) | |

| 1/2” | 340 | 95 | 80 | 85 | 200 | 120 | 13.4 | 3.7 | 3.1 | 3.3 | 7.9 | 4.7 | 28,0 | 61.6 |

| 3/4” | ||||||||||||||

| 1” | ||||||||||||||

| 1 1/4” | 390 | 15.4 | 32,0 | 70.4 | ||||||||||

| 1 1/2” | ||||||||||||||

| 2” | ||||||||||||||

*Available flange standards: ASME/JPI, DIN, JIS

*Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

Socket Weld

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||||||

| L | L1 | L2 | L3 | H1 | H2 | L | L1 | L2 | L3 | H1 | H2 | (kg) | (lb) | |

| 1/2” | 280 | 95 | 80 | 85 | 200 | 120 | 11.0 | 3.7 | 3.1 | 3.3 | 7.9 | 4.7 | 25,5 | 56.1 |

| 3/4” | ||||||||||||||

| 1” | ||||||||||||||

| Model | Connection |

Max. operating pressure |

Max. operating pressure differential |

Max. operating temperature |

Body material |

||||

| Type | Size | PMO(MPa) | PMO(psig) | ⊿PMX(MPa) | ⊿PMX(psig) | TMO(℃) | TMO(℉) | ||

| AGH29-16 |

Flanged* FF,RF |

1/2” | 3,0 | 435 | 1,6 | 232 | 400 | 752 |

Cast steel WCB |

| 3/4” | |||||||||

| 1” | |||||||||

| 1 1/4” | |||||||||

| 1 1/2” | |||||||||

| 2” | |||||||||

| AGH29-40 | 1/2” | 4,5 | 652 | 4,0 | 580 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

| 1 1/4” | |||||||||

| 1 1/2” | |||||||||

| 2” | |||||||||

| AGH29W-16 |

Socket Weld SW |

1/2” | 3,0 | 435 | 1,6 | 232 | 400 | 752 |

Cast steel WCB |

| 3/4” | |||||||||

| 1” | |||||||||

| AGH29W-40 | 1/2” | 4,5 | 652 | 4,0 | 580 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

*Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

* Membership registration is required to download the documents.