Steam Trap

Assessment Service

Do you perform regular maintenance on your steam traps?

Steam traps have a limited life span, and steam loss can occur due to deterioration of the valve and valve seat over time.

In order to minimize the loss of energy due to steam loss, steam traps must undergo regular assessment and maintenance.

The average defect rate for steam traps is 20 - 25%.

The steam trap assessment service offered by Miyawaki leverages the unique know-how that we have built up,

and delivers significant energy saving to customers with the goal of keeping the steam trap defect rate to less than 5%.

Benefits of assessment

- 1

Precise assessments by certified assessment technicians

Assessments are performed by assessors who have achieved certification under Miyawaki’s own skill certification system

- 2

Reselection of highly durable steam traps

- 3

Suggestions to pipe arrangement improvements to increase productivity

Ensuring the steam trap defect rate is reduced and kept low and that an ongoing, drastic reduction in steam loss is achieved

-

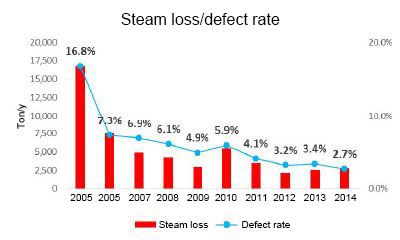

Steam trap defect rate (example)

- Traps inspected: approx. 8,000

- Red: Steam loss

- Blue: Defect rate

-

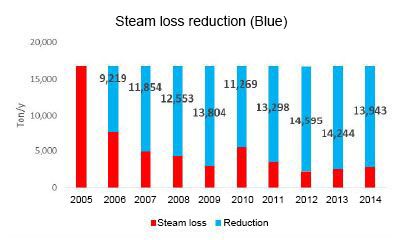

Steam loss reduction (example)

- Traps inspected: approx. 8,000

- Red: Steam loss

- Blue: Steam loss reduction (volume steam loss reduced by from first year)

As shown by the graph above, implementing steam trap assessments and maintenance

enables drastic savings in terms of costs and energy.

Service Overview

- 1

Consultation and meeting

Confirmation of number of traps for assessment, assessment period, and installation circumstances

- 2

Submission of estimate

- 3

On site survey

Creation of installation diagram and management ledger, and attachment of management labels, etc.

- 4

Assessment

Assessment of steam traps, bypass valves, and prior/subsequent valves, determination of suitability of trapping, etc.

- 5

Assessment results report, suggestions for improvement

Assessment aggregate analysis, estimated steam loss volume/steam loss cash amount, selection of recommended products to use in replacement, etc.

- 6

Maintenance performed by customer

- 7

Confirmation of effect through regular assessment, ongoing management

Steps ❶ - ❼ should be repeated regularly.

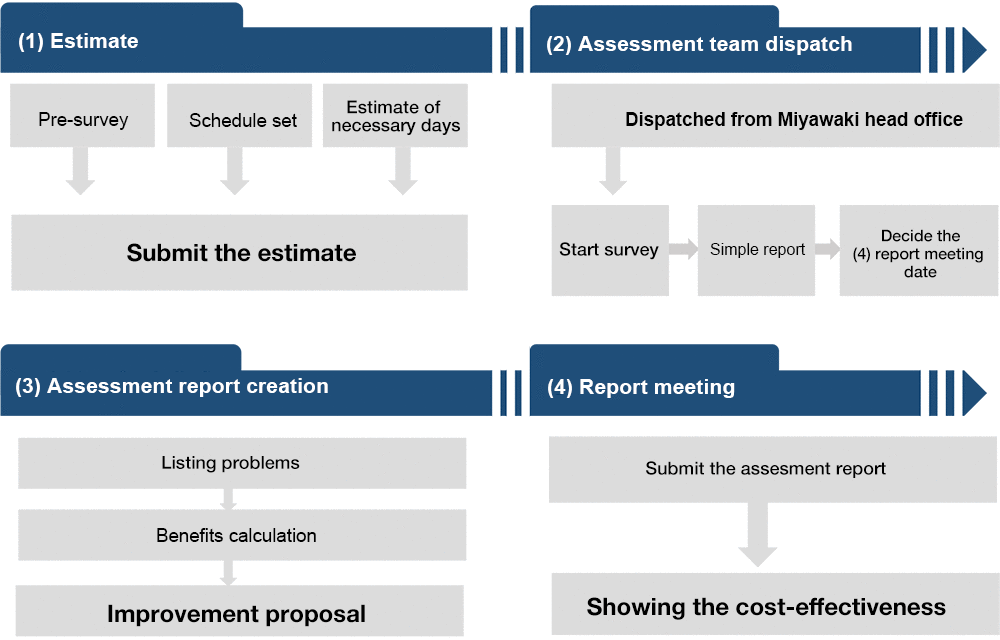

Walking Survey

Points covered in a walking survey

- ■ Boilers and peripheral equipment

- ■ Main steam lines

- ■ Steam process devices

- ■ Condensate recovery

- ■ Steam traps

- ■ Locations with problems identified through prior research

- etc.

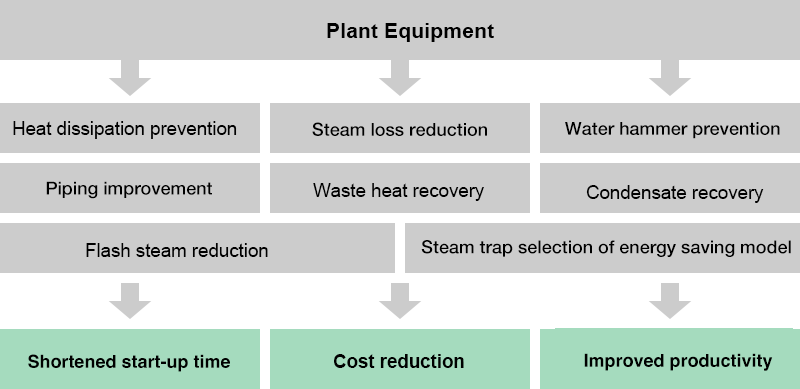

Achievable improvements

Overview of support for achieving improvements

Miyawaki will show you how you can achieve energy savings and efficiency through your steam system as a whole

*Feel free to inquire at your nearest sales office or branch.