Q-Plus Jacket Thermal Insulation Cover

Ancillary Equipment Q-Plus Jacket Thermal Insulation Cover

QH / QAG

Features/Applications

Features

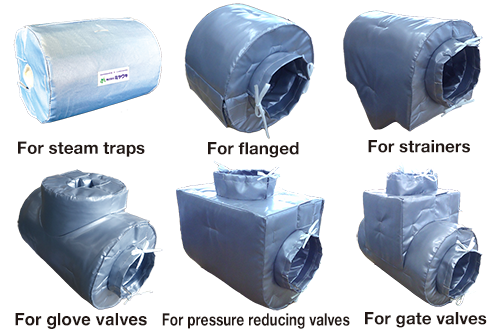

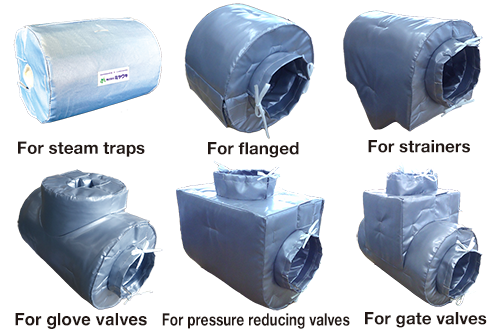

Customized manufacturing available

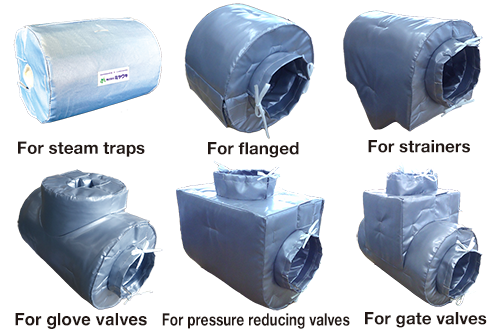

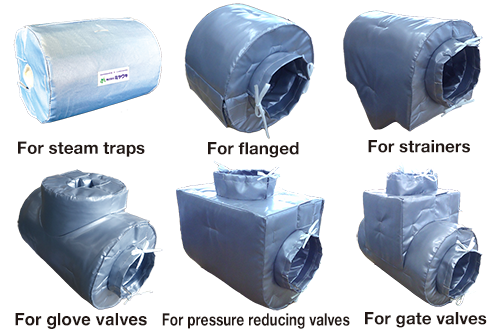

No matter how complex, this product can be manufactured in any shape to fit the device or component for thermal insulation.

Top class insulation performance

Uses material with extremely low heat conductivity.

Depending on the materials used, the safe operating temperature can reach a maximum of 1000℃ (1832°F).

With a material suitable for the application and manufacturing using three-dimensional forming, there are no gaps for heat to leak out of and this results in top class insulation.

Environmentally friendly design with simple attachment and detachment

With a structure that uses hook-and-loop fasteners and other such things, this product can be attached and detached by anyone, and can be used repeatedly.

The QAG model is made from high-quality material that can be used long term in harsh conditions both indoors and outdoors.

High water-repellent properties

The aerogel type (QAG model) has high water-repellent properties.

Typical applications

Perfect for thermal insulation on all elements of any steam system, including lines, valves, boilers, and steam traps.

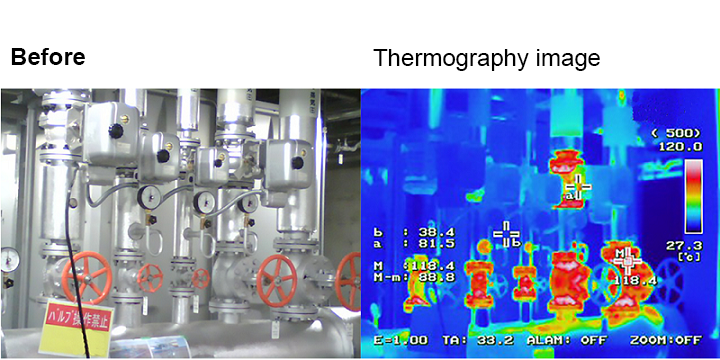

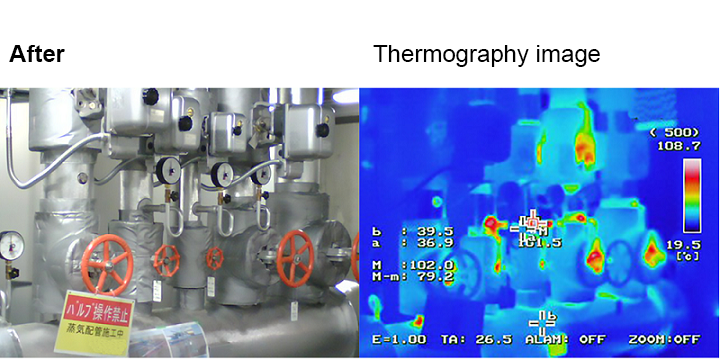

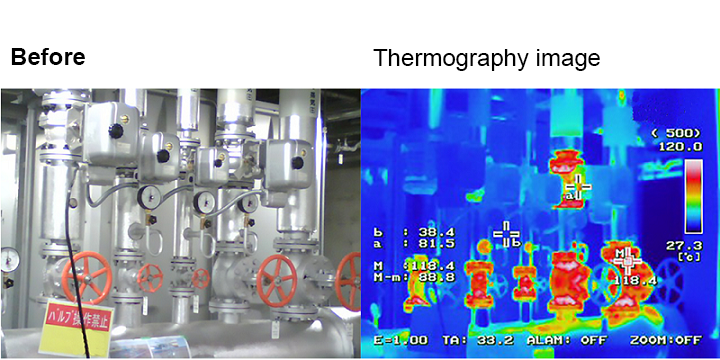

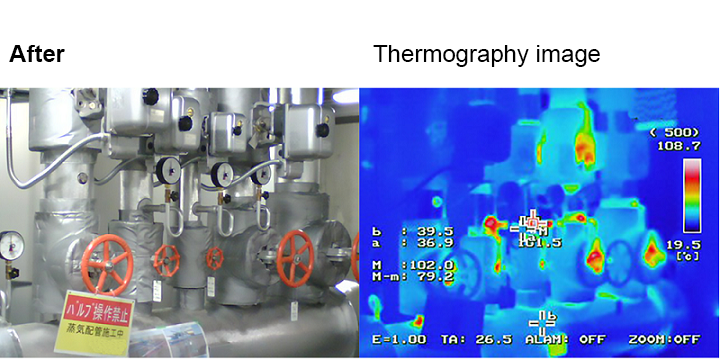

Example usage

Energy saving effect

● Example energy reduction and steam cost saving when the Q-Plus Jacket is used

(Below is an example of pipes and devices used in a boiler room)

Energy reduction: 50,000MJ/year (steam equivalent of 25.3 tons/year)

Steam cost saving: 126,700 yen/year approx.

● Applicable devices

| Pressure reducing valves | 40A, JIS 10K |

| Y strainers | 40A, JIS 10K |

| Stop valves x2 | 40A, JIS 10K |

●Conditions

| Pressure reducing valves | Primary-side pressure 0,8MPa(116psig), Secondary-side pressure 0,4MPa(58psig) |

| Indoor temperature | 15℃ (59°F) |

| Steam cost | Steam cost 5,000 yen/ton |

| Hours in operation | 24 hrs/day |

| Days in operation | 330 days/year |

Specifications

| Model | QH25S-T |

QH50S-T |

QAG25S-T | QAG50S-T | |

|

Usage location |

Indoors | Indoors/outdoors | |||

| Material |

Jacket material Max. operating temperature |

Silicon coated glass cloth 180℃ |

PTFE coated glass cloth 260℃ |

||

|

Inner coating Max. operating temperature |

Glass cloth 500℃ |

||||

| Insulation material (outer) | Needled glass mat |

Aerogel (5mm) |

Aerogel (10mm) |

||

| Insulation material (inner) |

Needled glass mat (20mm) |

Needled glass mat (40mm) |

|||

| Insulation thickness | 25 mm 1.0in |

50 mm 2.0in |

25mm 1.0in |

50mm 2.0in |

|

| Sewing fiber |

Glass fiber |

PTFE fiber | |||

| Attachment method | Hook-and-loop fasteners | Hook-and-loop fasteners | |||

| Color | Silver | Silver | |||

| Safe operating temperature |

Up to 500℃ Up to 932°F |

Up to 260℃ Up to 500°F |

|||

Optional Specifications

*In addition to the standard specifications, the following specifications can also be selected.

| Models for reference | QH25*1 |

QH50*1 |

QAG25*1 | QAG50*1 | |

| Material |

Jacket material Max. operating temperature |

PTFE coated glass cloth/260℃ (500℉) Aluminum coated glass cloth/160℃ (320℉) |

― |

||

|

Inner coating Max. operating temperature |

Silica cloth 700℃ or 1000℃ |

Glass cloth 500℃ |

|||

| Insulation material (outer) |

Mineral wool Glass wool Super wool (biosoluble wool) |

― |

― |

||

| Insulation material (inner) |

― |

― |

|||

| Sewing fiber |

PTFE fiber or SUS fiber or silica fiber |

― | |||

| Attachment method | Glass sleeve strap (R) or D ring belt (B) | D ring belt (B) | |||

| Color | Blue | Blue | |||

| Safe operating temperature | Up to 700℃ or 1000℃ Up to 1292°F or 1832°F*2 |

Up to 500℃ Up to 932°F*2 |

|||

*1 Model name differs depending on the model chosen.

*2 The safe operating temperature depends on the material (inner coating) used.

*As well as the above, customization according to use and order made production (shape) are available. Please do not hesitate to make inquiries.

Lineup

Download

* Membership registration is required to download the documents.

Features

Customized manufacturing available

No matter how complex, this product can be manufactured in any shape to fit the device or component for thermal insulation.

Top class insulation performance

Uses material with extremely low heat conductivity.

Depending on the materials used, the safe operating temperature can reach a maximum of 1000℃ (1832°F).

With a material suitable for the application and manufacturing using three-dimensional forming, there are no gaps for heat to leak out of and this results in top class insulation.

Environmentally friendly design with simple attachment and detachment

With a structure that uses hook-and-loop fasteners and other such things, this product can be attached and detached by anyone, and can be used repeatedly.

The QAG model is made from high-quality material that can be used long term in harsh conditions both indoors and outdoors.

High water-repellent properties

The aerogel type (QAG model) has high water-repellent properties.

Typical applications

Perfect for thermal insulation on all elements of any steam system, including lines, valves, boilers, and steam traps.

Example usage

Energy saving effect

● Example energy reduction and steam cost saving when the Q-Plus Jacket is used

(Below is an example of pipes and devices used in a boiler room)

Energy reduction: 50,000MJ/year (steam equivalent of 25.3 tons/year)

Steam cost saving: 126,700 yen/year approx.

● Applicable devices

| Pressure reducing valves | 40A, JIS 10K |

| Y strainers | 40A, JIS 10K |

| Stop valves x2 | 40A, JIS 10K |

●Conditions

| Pressure reducing valves | Primary-side pressure 0,8MPa(116psig), Secondary-side pressure 0,4MPa(58psig) |

| Indoor temperature | 15℃ (59°F) |

| Steam cost | Steam cost 5,000 yen/ton |

| Hours in operation | 24 hrs/day |

| Days in operation | 330 days/year |

| Model | QH25S-T |

QH50S-T |

QAG25S-T | QAG50S-T | |

|

Usage location |

Indoors | Indoors/outdoors | |||

| Material |

Jacket material Max. operating temperature |

Silicon coated glass cloth 180℃ |

PTFE coated glass cloth 260℃ |

||

|

Inner coating Max. operating temperature |

Glass cloth 500℃ |

||||

| Insulation material (outer) | Needled glass mat |

Aerogel (5mm) |

Aerogel (10mm) |

||

| Insulation material (inner) |

Needled glass mat (20mm) |

Needled glass mat (40mm) |

|||

| Insulation thickness | 25 mm 1.0in |

50 mm 2.0in |

25mm 1.0in |

50mm 2.0in |

|

| Sewing fiber |

Glass fiber |

PTFE fiber | |||

| Attachment method | Hook-and-loop fasteners | Hook-and-loop fasteners | |||

| Color | Silver | Silver | |||

| Safe operating temperature |

Up to 500℃ Up to 932°F |

Up to 260℃ Up to 500°F |

|||

Optional Specifications

*In addition to the standard specifications, the following specifications can also be selected.

| Models for reference | QH25*1 |

QH50*1 |

QAG25*1 | QAG50*1 | |

| Material |

Jacket material Max. operating temperature |

PTFE coated glass cloth/260℃ (500℉) Aluminum coated glass cloth/160℃ (320℉) |

― |

||

|

Inner coating Max. operating temperature |

Silica cloth 700℃ or 1000℃ |

Glass cloth 500℃ |

|||

| Insulation material (outer) |

Mineral wool Glass wool Super wool (biosoluble wool) |

― |

― |

||

| Insulation material (inner) |

― |

― |

|||

| Sewing fiber |

PTFE fiber or SUS fiber or silica fiber |

― | |||

| Attachment method | Glass sleeve strap (R) or D ring belt (B) | D ring belt (B) | |||

| Color | Blue | Blue | |||

| Safe operating temperature | Up to 700℃ or 1000℃ Up to 1292°F or 1832°F*2 |

Up to 500℃ Up to 932°F*2 |

|||

*1 Model name differs depending on the model chosen.

*2 The safe operating temperature depends on the material (inner coating) used.

*As well as the above, customization according to use and order made production (shape) are available. Please do not hesitate to make inquiries.

* Membership registration is required to download the documents.