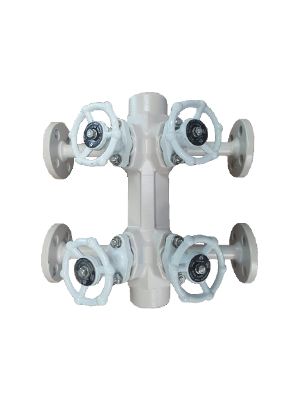

Steam/Condensate Manifold

Manifold Series Steam/Condensate Manifold

MM_P&FMM

Features/ Applications

Features

Compact design

Reduce the installation space and organize the system.

Easy handling

Installation, maintenance, and replacement are simple, leading to easy inspection and lower labor costs. In combination with a UNC connector, steam traps with a two-bolt connection can be installed and replaced without disassembling the manifold (package) unit.

Pressure Equipment Directive (PED) Certified

Typical applications

Suitable for steam distribution and condensate collection that simplifies your steam management.

Specifications

Forged Steel

|

Model |

Integrated |

Max. |

Max. |

Body |

Connection |

Number of |

Connection |

Min. |

Hydrotest |

Kv Values |

Approx. |

Body material |

|

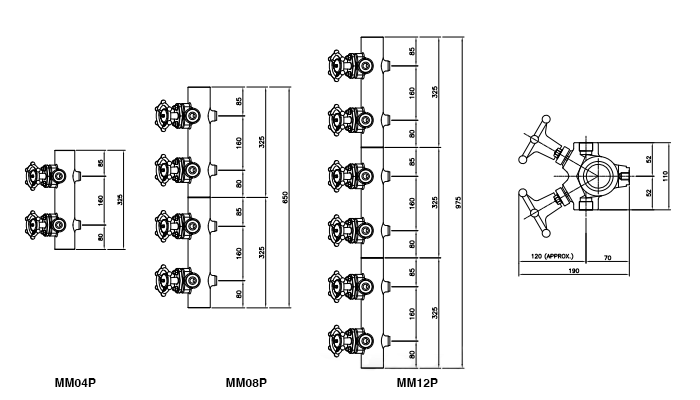

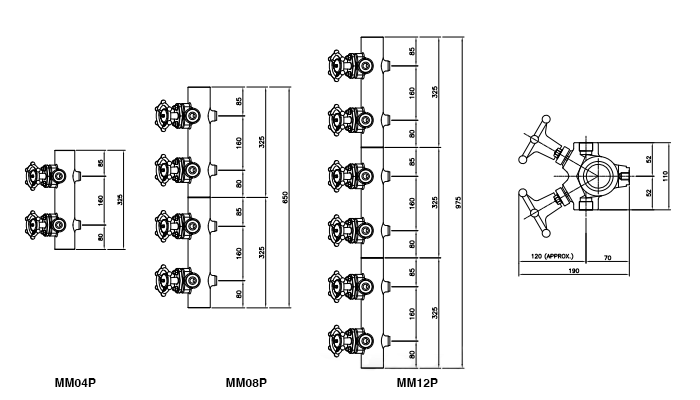

MM04P |

Piston Valve |

5.17MPa |

425℃ |

1-1/2”, |

NPT, SW |

4 |

1/2”, 3/4” |

-29℃ |

7.75MPa |

2.0 |

10 |

Forged steel A105 |

|

MM08P |

8 |

20 |

||||||||||

|

MM12P |

12 |

30 |

*PMO ASME 300, SW, NPT 4.15MPa

*TMO ASME 300, SW, NPT 425℃ @ 2.8MPa

(*Compact Manifold Packages are restricted by attached valves and traps.)

Fabricated Steel

|

Model |

Integrated |

Max. Allowable |

Max. Allowable |

Body Inlet/ |

Connection Type |

Number of |

Connection |

Min. Allowable |

Hydrotest |

Approx. |

Body material |

|

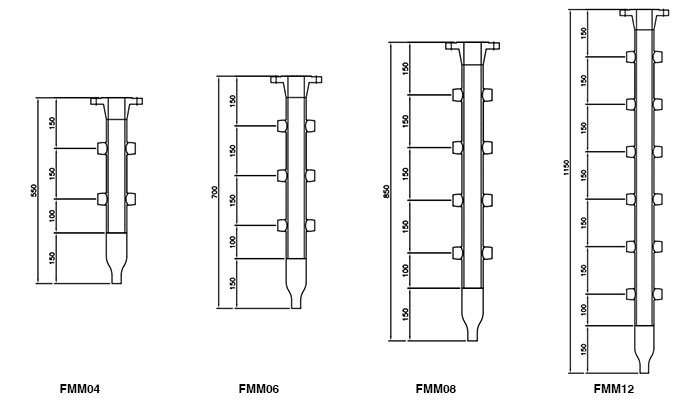

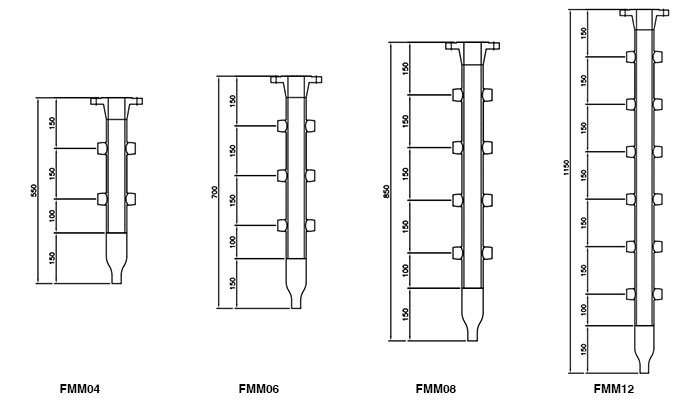

FMM04 |

- |

4.26MPa |

425℃ |

1/2" - 2" |

NPT, SW |

4 |

1/2”, 3/4” |

-29℃ |

6.39MPa |

11 |

Fabricated steel A106-B |

|

FMM06 |

6 |

15 |

|||||||||

|

FMM08 |

8 |

18 |

|||||||||

|

FMM10 |

10 |

23 |

|||||||||

|

FMM12 |

12 |

26 |

*PMO ASME 300, SW, NPT 4.15MPa

*TMO ASME 300, SW, NPT 240℃ @ 2.7MPa

(*Fabricated Manifold Packages conform to client’ s spec. and are restricted by attached valves and traps.)

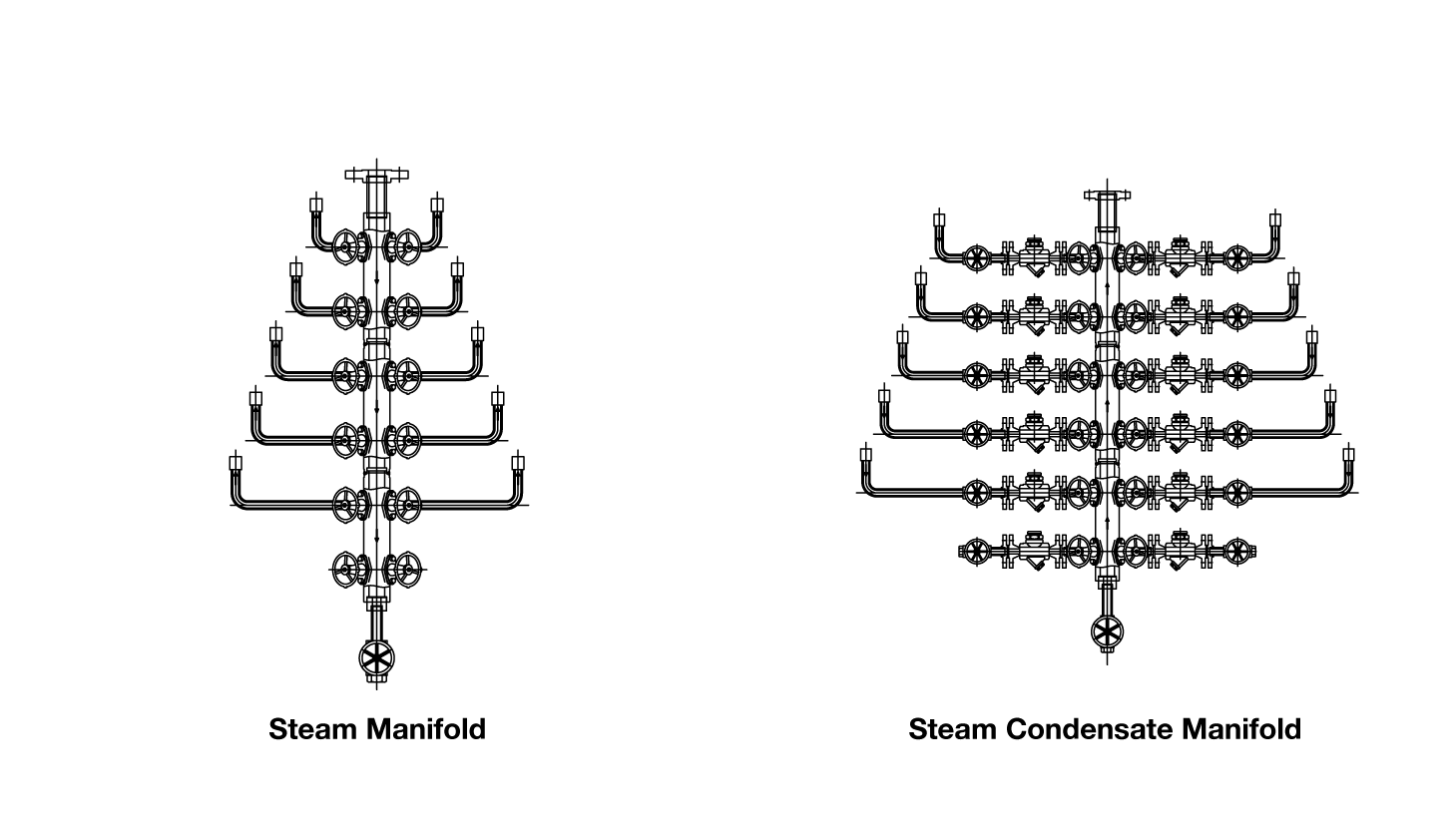

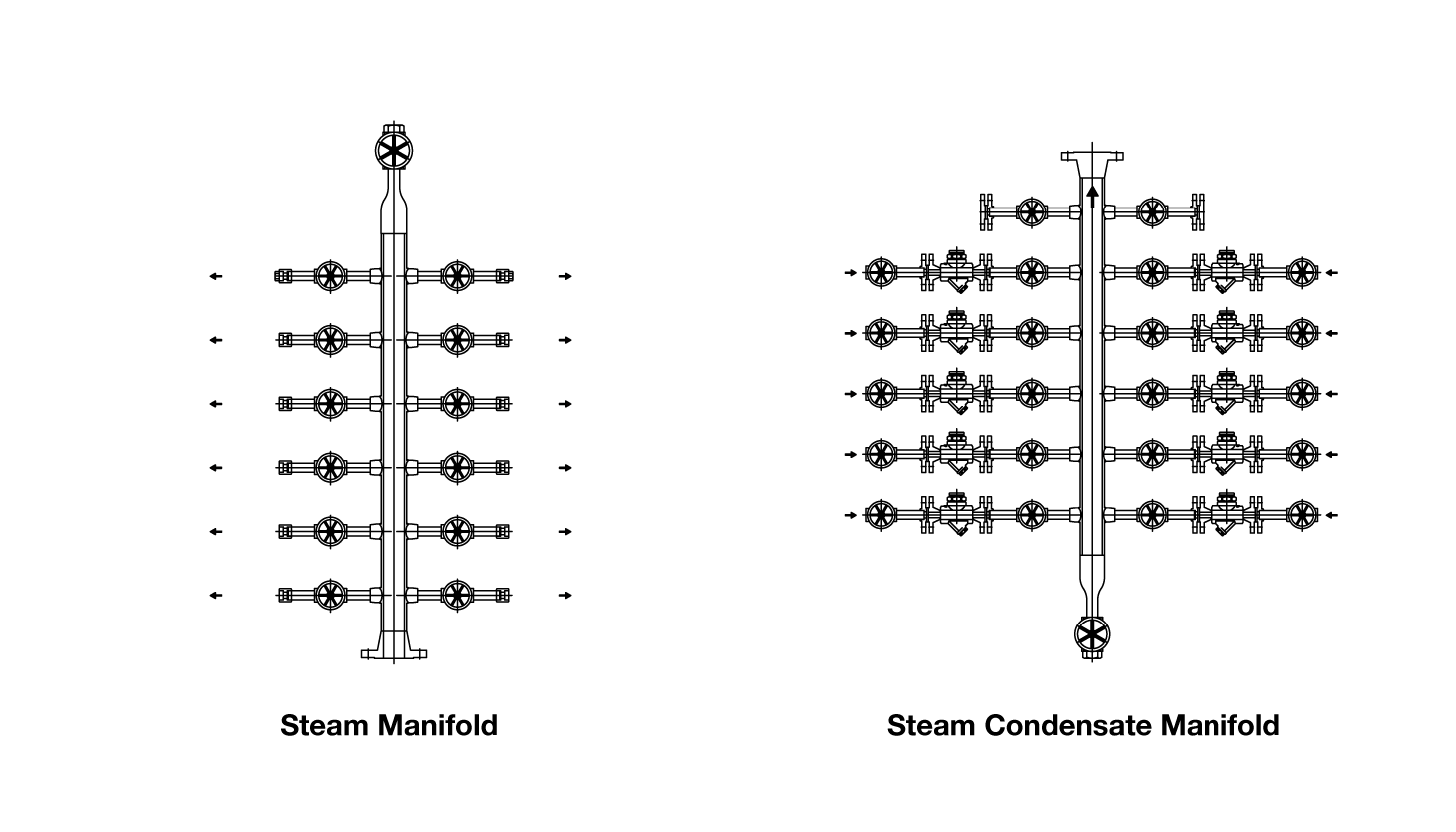

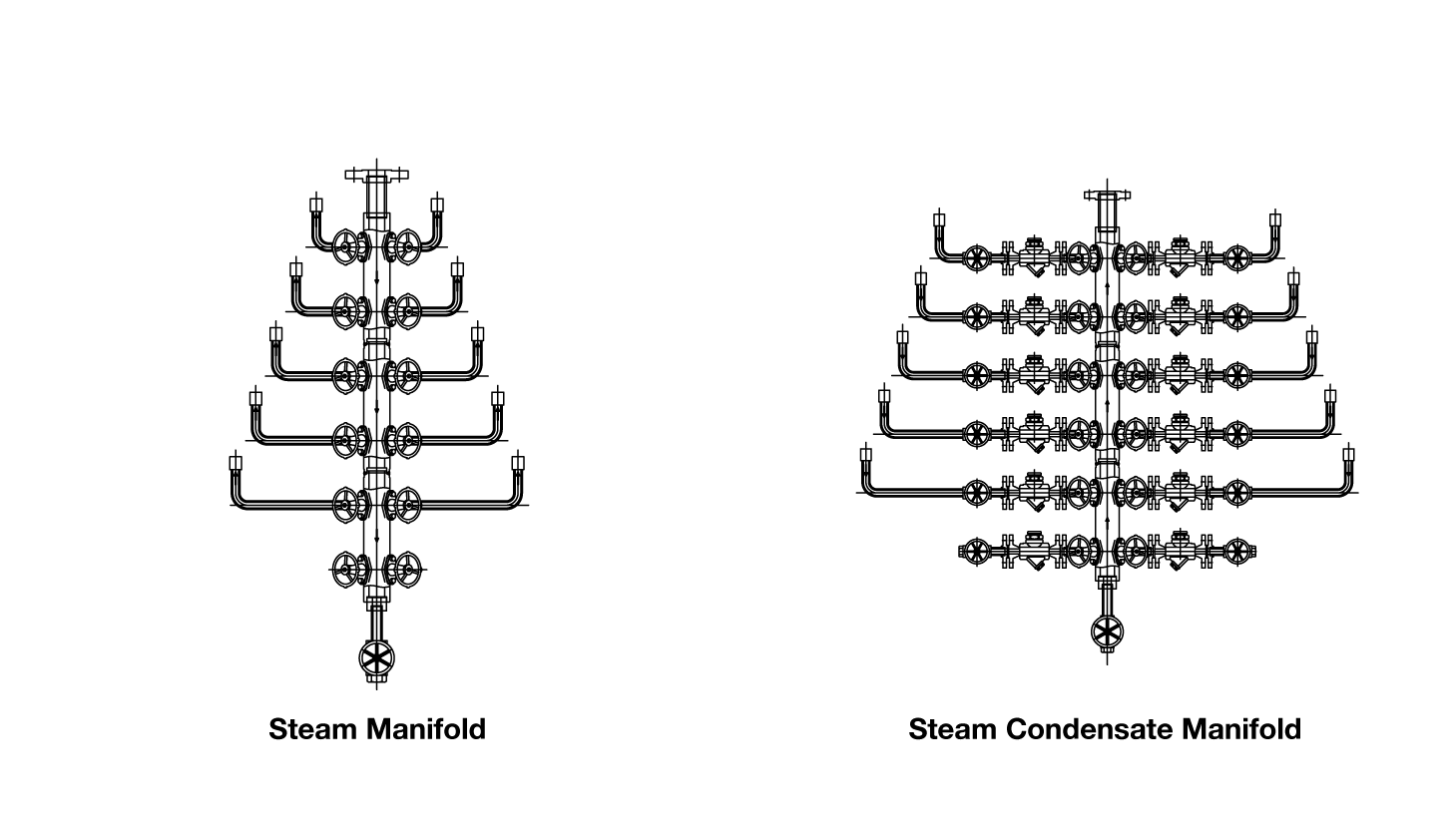

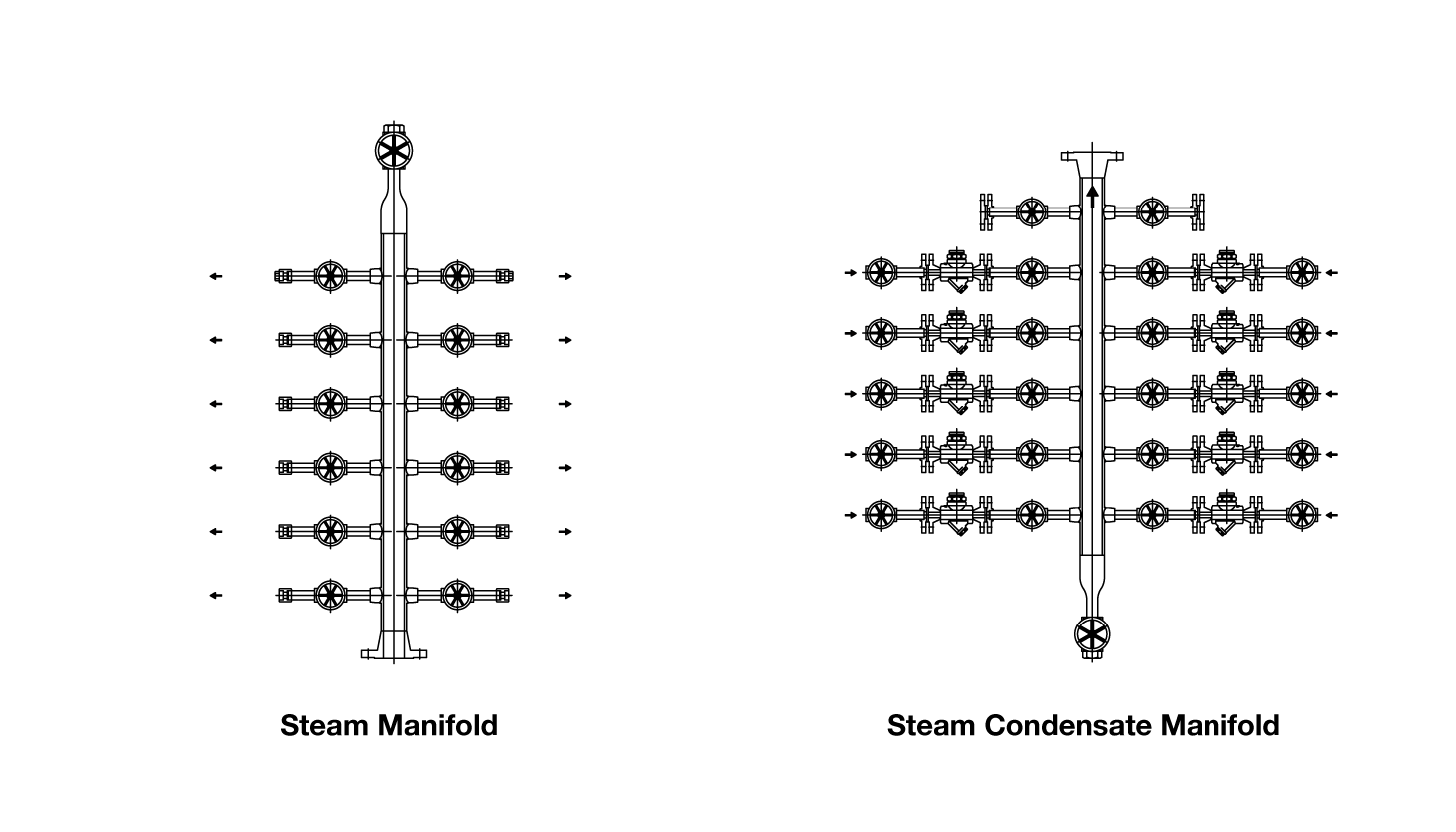

Package Examples

Forged Steel

Fabricated Steel

●Recommendation

・Steam Traps with Two-Bolt Connection | MIYAWAKI Inc. (miyawaki-inc.com)

・Two-Bolt Connectors | MIYAWAKI Inc. (miyawaki-inc.com)

Options

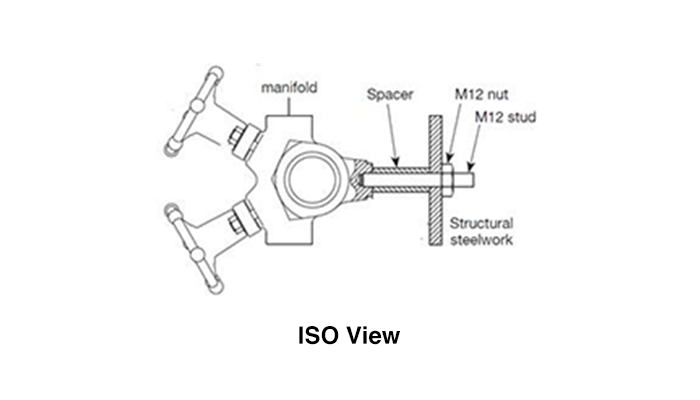

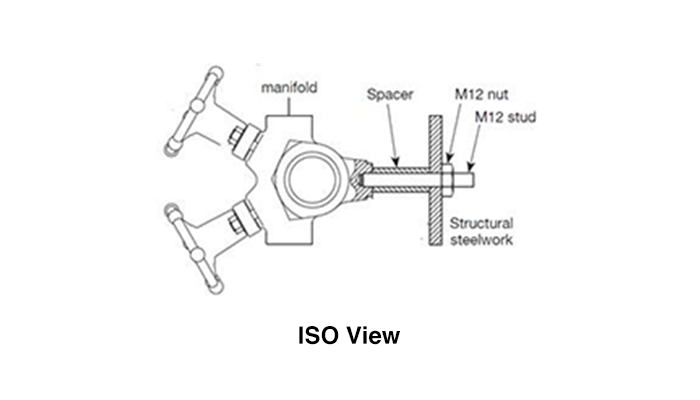

■Mounting Kit

For ease of installation and insulation, an optional mounting kit is available which will provide a 2” stand-off from any adjacent structure.

The kit consists of a threaded studs, spacers and nuts, designed to match the M12 mounting holes on the back of the manifold.

The following sets are available:

4 way manifolds: Single set with 2 studs, nuts and spacers

8 way manifolds: Single set with 3 studs, nuts and spacers

12 way manifolds: Single set with 4 studs, nuts and spacers

■Structural Steelwork (Stand)

Customized structural steelwork (stand) is available to mount the manifold.

■Insulating Jacket

Customized insulating jackets are available to protect personnel from burn risks and to minimize radiated heat losses.

■Immersion Tube / Siphon Tube

Immersion Tube / Siphon Tube for condensate manifold is available to meet the requirement.

Download

* Membership registration is required to download the documents.

Features

Compact design

Reduce the installation space and organize the system.

Easy handling

Installation, maintenance, and replacement are simple, leading to easy inspection and lower labor costs. In combination with a UNC connector, steam traps with a two-bolt connection can be installed and replaced without disassembling the manifold (package) unit.

Pressure Equipment Directive (PED) Certified

Typical applications

Suitable for steam distribution and condensate collection that simplifies your steam management.

Forged Steel

|

Model |

Integrated |

Max. |

Max. |

Body |

Connection |

Number of |

Connection |

Min. |

Hydrotest |

Kv Values |

Approx. |

Body material |

|

MM04P |

Piston Valve |

5.17MPa |

425℃ |

1-1/2”, |

NPT, SW |

4 |

1/2”, 3/4” |

-29℃ |

7.75MPa |

2.0 |

10 |

Forged steel A105 |

|

MM08P |

8 |

20 |

||||||||||

|

MM12P |

12 |

30 |

*PMO ASME 300, SW, NPT 4.15MPa

*TMO ASME 300, SW, NPT 425℃ @ 2.8MPa

(*Compact Manifold Packages are restricted by attached valves and traps.)

Fabricated Steel

|

Model |

Integrated |

Max. Allowable |

Max. Allowable |

Body Inlet/ |

Connection Type |

Number of |

Connection |

Min. Allowable |

Hydrotest |

Approx. |

Body material |

|

FMM04 |

- |

4.26MPa |

425℃ |

1/2" - 2" |

NPT, SW |

4 |

1/2”, 3/4” |

-29℃ |

6.39MPa |

11 |

Fabricated steel A106-B |

|

FMM06 |

6 |

15 |

|||||||||

|

FMM08 |

8 |

18 |

|||||||||

|

FMM10 |

10 |

23 |

|||||||||

|

FMM12 |

12 |

26 |

*PMO ASME 300, SW, NPT 4.15MPa

*TMO ASME 300, SW, NPT 240℃ @ 2.7MPa

(*Fabricated Manifold Packages conform to client’ s spec. and are restricted by attached valves and traps.)

Forged Steel

Fabricated Steel

●Recommendation

・Steam Traps with Two-Bolt Connection | MIYAWAKI Inc. (miyawaki-inc.com)

・Two-Bolt Connectors | MIYAWAKI Inc. (miyawaki-inc.com)

■Mounting Kit

For ease of installation and insulation, an optional mounting kit is available which will provide a 2” stand-off from any adjacent structure.

The kit consists of a threaded studs, spacers and nuts, designed to match the M12 mounting holes on the back of the manifold.

The following sets are available:

4 way manifolds: Single set with 2 studs, nuts and spacers

8 way manifolds: Single set with 3 studs, nuts and spacers

12 way manifolds: Single set with 4 studs, nuts and spacers

■Structural Steelwork (Stand)

Customized structural steelwork (stand) is available to mount the manifold.

■Insulating Jacket

Customized insulating jackets are available to protect personnel from burn risks and to minimize radiated heat losses.

■Immersion Tube / Siphon Tube

Immersion Tube / Siphon Tube for condensate manifold is available to meet the requirement.

* Membership registration is required to download the documents.