Direct Acting for liquids and gases

Pressure Reducing Valves Direct Acting for liquids and gases

REA20

Features/Applications

Features

Self-acting pressure reducing valves for liquids and gases

The model REA20 is a direct acting pressure reducing valve designed for compressible media, such as air and various gasses and for incompressible media such as water, oil and others. The valve is self acting and does not require external energy.

Wide range of pressure reduction

Due to careffully selected springs an outstanding reduction ratio of 25:1 is achieved.

Superb durability

Highly durable and carefully selected components, a 360° free rotating, conical plug and the lack of a sensitive diaphragm ensure outstanding lifetime of this valve.

Operating features of direct acting pressure reducing valves

Pressure changes on the downstream side are detected in the detection chamber, and the degree of opening of the valve is directly adjusted to keep the pressure on the downstream side at set pressure.

Diaphram free design

The valve operates with an O-ring sealing and a piston design. Due to this design, no daiphragm and no external sensing line is required.

Options available

- additional pressure gauges

- tailored connections for special applications

- softsealing for leakage class VI

Typical applications

Ideally installed in any fluid system or technical gases, such as lube oil lines, pre-heater units, natural gas lines, pressurized air lines, LNG or gasoline tank systems. Fits perfectly for other technical gases such as Atzetylene, Ammonia, Carbondioxide.

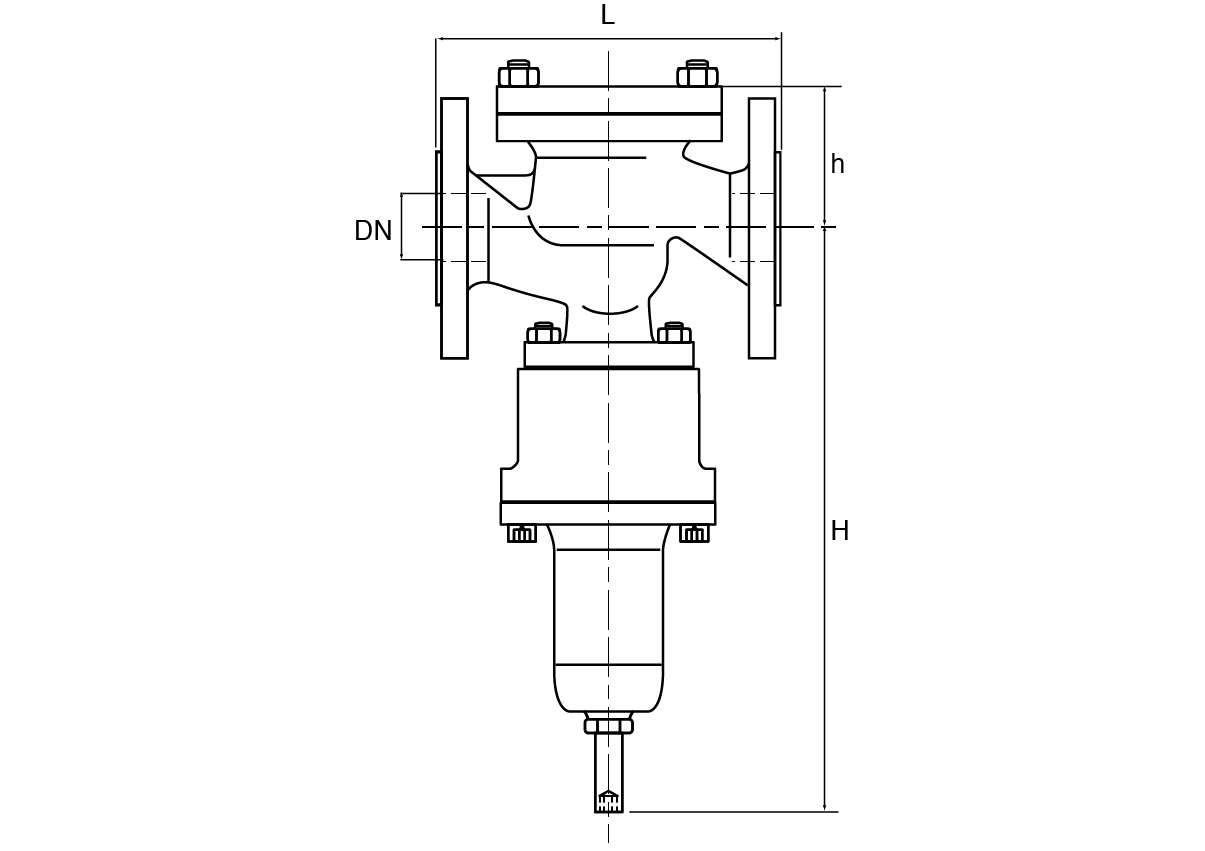

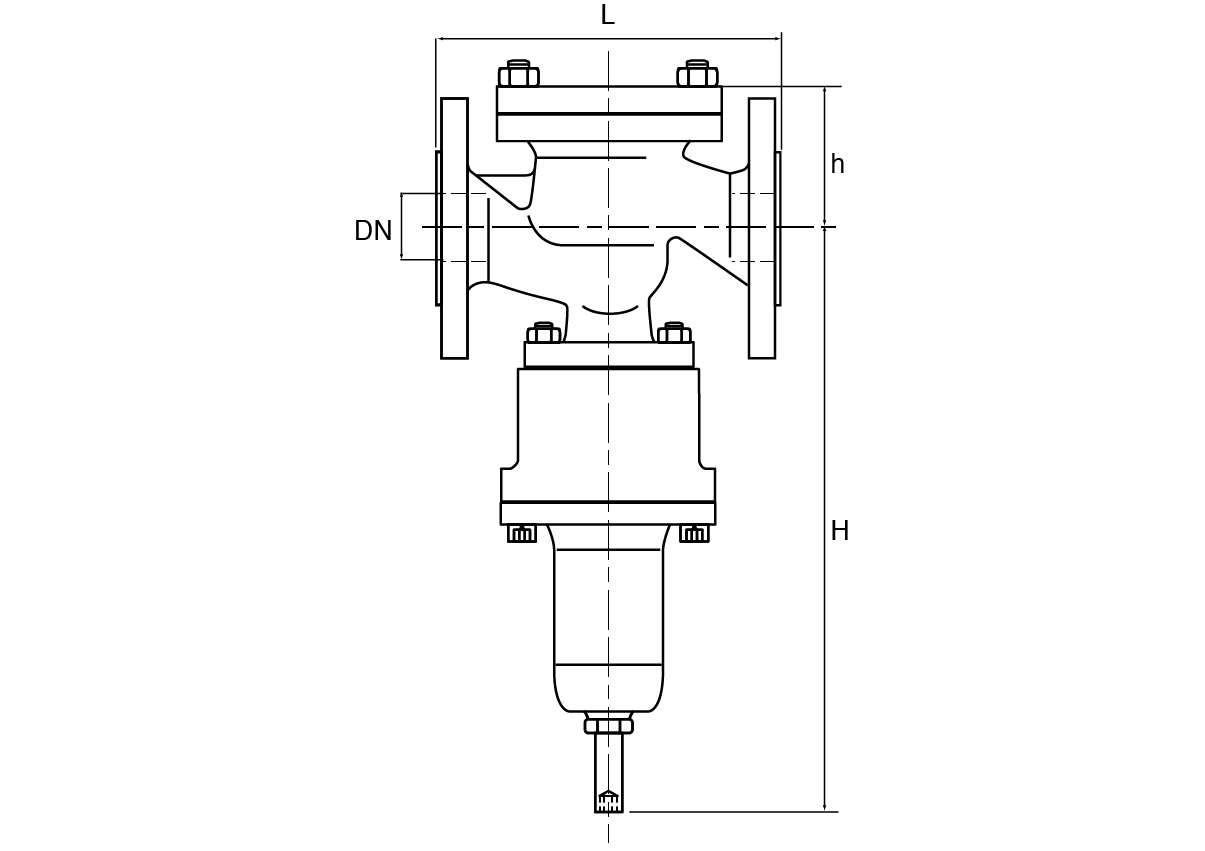

Dimensions/Weight

Dimensions/Weight

|

Size (DN) |

Dimensions (mm) |

Kvs Value |

Weight (kg) |

||

| L | H | h | |||

| 15 | 130 | 310 | 90 | 8,0 | 10,5 |

| 20 | 150 | 11,0 | 10,5 | ||

| 25 | 160 | 12,0 | 12,0 | ||

| 32 | 180 | 330 | 120 | 12,0 | 14,5 |

| 40 | 200 | 114,0 | 15,5 | ||

| 50 | 230 | 435 | 130 | 63,0 | 28,5 |

| 65 | 290 | 465 | 155 | 92,0 | 37,0 |

| 80 | 310 | 630 | 180 | 113,0 | 56,5 |

| 100 | 350 | 655 | 150,0 | 69,0 | |

| 125 | 400 | 660 | 210 | 196,0 | 120,0 |

| 150 | 480 | 680 | 235 | 321,0 | 183,0 |

| 200 | 600 | 740 | 285 | 483,0 | 358,0 |

Specifications

| PN16 | PN25 | |

| Max. design pressure (MPa) PMA | 1,6 | 2,5 |

| Max. design temperature (℃) TMA | 350 | 350 |

| Max. operating pressure (MPa) PMO | 1,6 | 2,5 |

| Max. operating temperature (℃) TMO | 350 | 350 |

| PN | Temperature ℃ | ||||||

| -10・・・+50 | 100 | 150 | 200 | 250 | 300 | 350 | |

| Pressure MPa | |||||||

| PN16 | 1,6 | 1,6 | 1,6 | 1,5 | 1,4 | 1,3 | 1,1 |

| PN25 | 2,5 | 2,5 | 2,4 | 2,3 | 2,2 | 2,0 | 1,8 |

|

Secondary pressure range |

DN15-DN40 | DN50 | DN65 | DN80 | DN100 | DN125-DN200 |

| MPa | Spring number per size | |||||

| < 0,05 | On request | On request | ||||

| 0,05-0,1 | 9 | 28 | 27 | 38 | 37 | |

| 0,1-0,16 | 8 | 27 | 26 | 37 | 36 | |

| 0,16-0,25 | 7 | 26 | 25 | 36 | 35 | |

| 0,25-0,4 | 6 | 25 | 24 | 35 | 34 | |

| 0,4-0,63 | 5 | 24 | 23 | 34 | 33 | |

| 0,63-1,0 | 4 | 23 | 22 | 33 | 32 | |

| 1,0-1,6 | 3 | 22 | 21 | 32 | 32 | |

| > 1,6 | On request | |||||

Secondary pressure ranges higher than 1,6 MPa and lower than 0,05 MPa on request available.

A minimum differential pressure of 0,05 MPa is required.

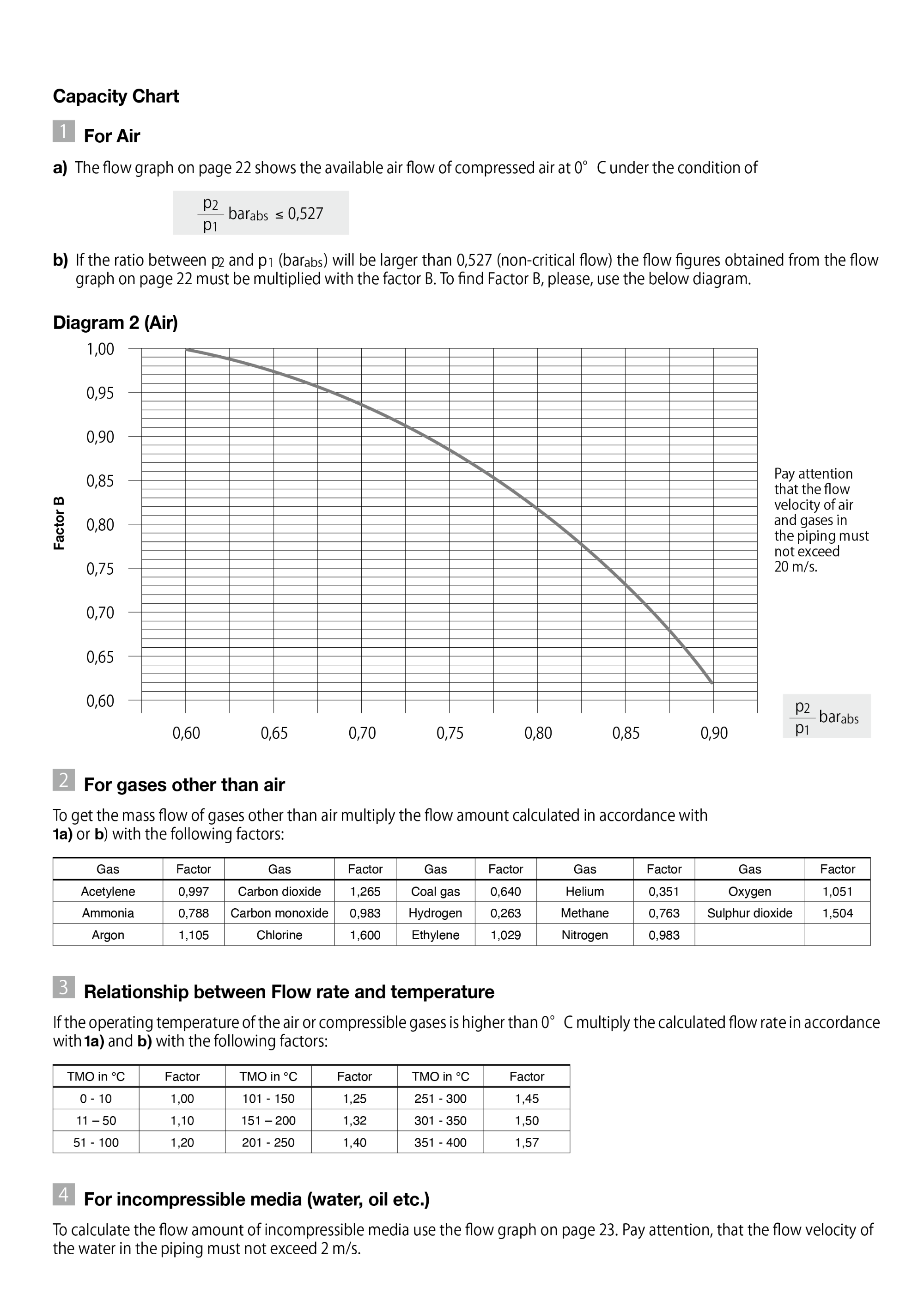

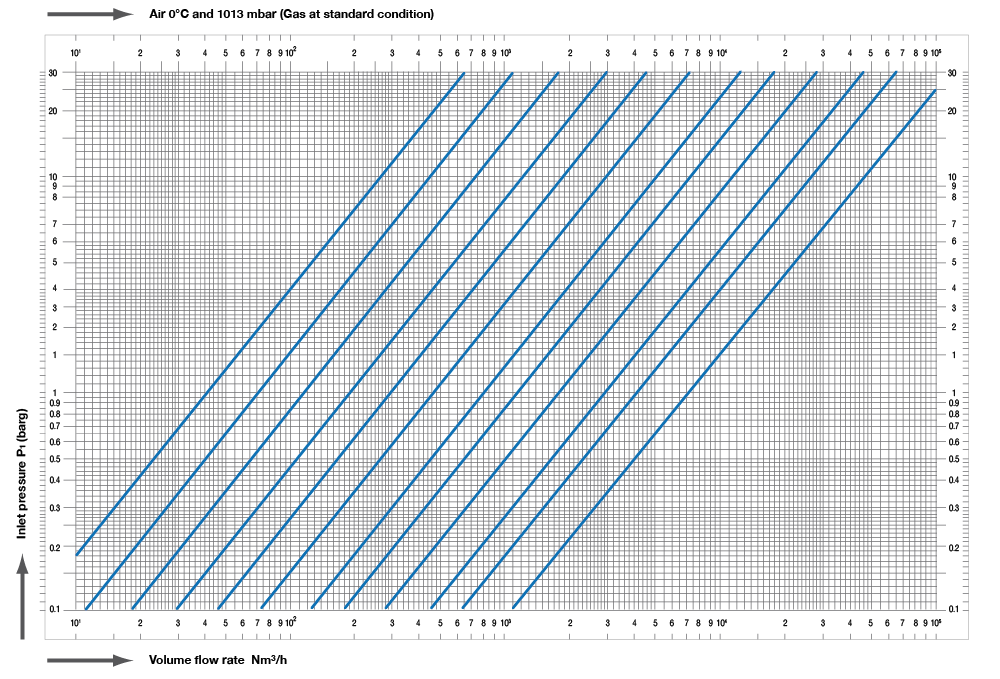

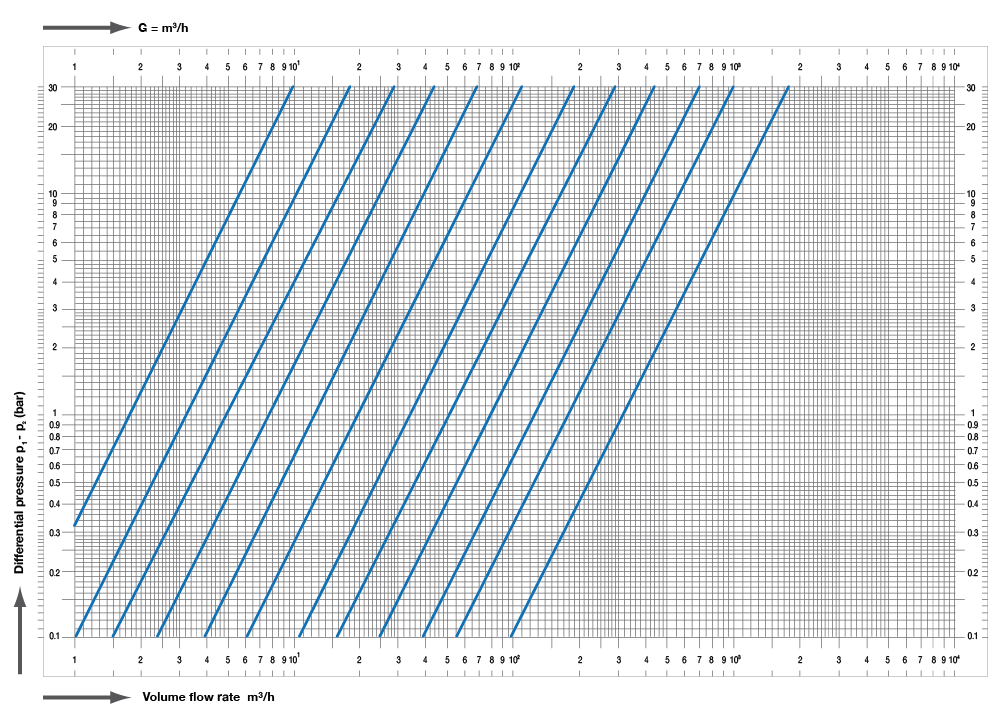

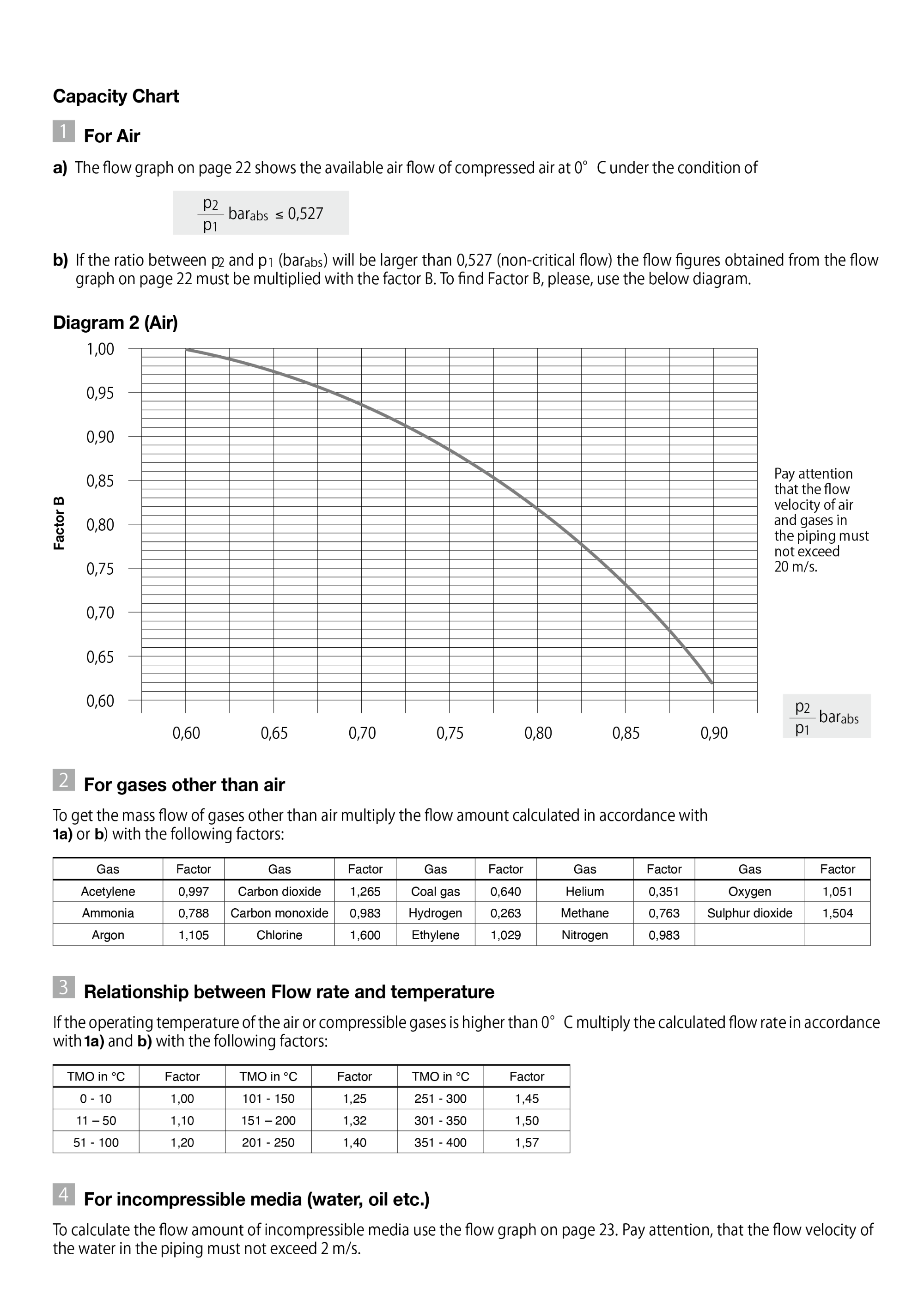

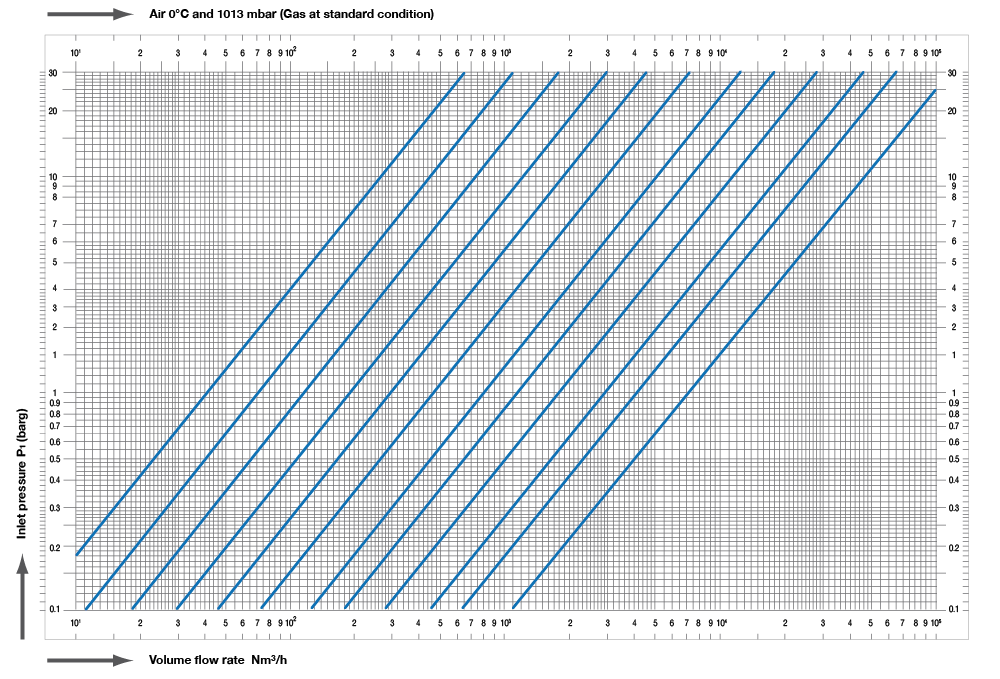

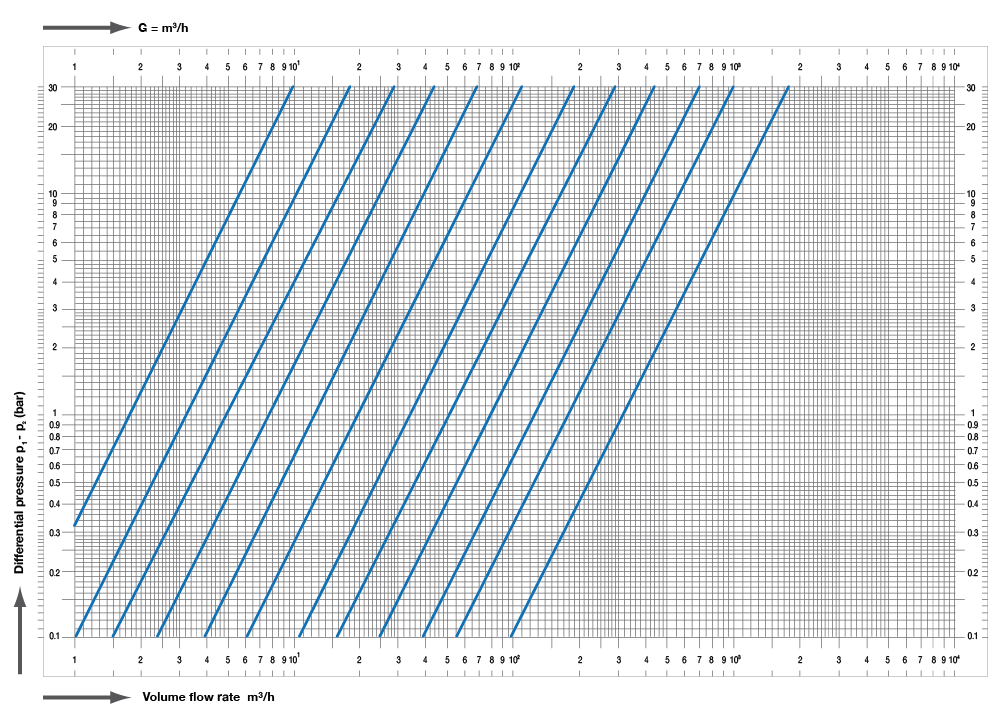

Capacity Chart

Download

* Membership registration is required to download the documents.

Features

Self-acting pressure reducing valves for liquids and gases

The model REA20 is a direct acting pressure reducing valve designed for compressible media, such as air and various gasses and for incompressible media such as water, oil and others. The valve is self acting and does not require external energy.

Wide range of pressure reduction

Due to careffully selected springs an outstanding reduction ratio of 25:1 is achieved.

Superb durability

Highly durable and carefully selected components, a 360° free rotating, conical plug and the lack of a sensitive diaphragm ensure outstanding lifetime of this valve.

Operating features of direct acting pressure reducing valves

Pressure changes on the downstream side are detected in the detection chamber, and the degree of opening of the valve is directly adjusted to keep the pressure on the downstream side at set pressure.

Diaphram free design

The valve operates with an O-ring sealing and a piston design. Due to this design, no daiphragm and no external sensing line is required.

Options available

- additional pressure gauges

- tailored connections for special applications

- softsealing for leakage class VI

Typical applications

Ideally installed in any fluid system or technical gases, such as lube oil lines, pre-heater units, natural gas lines, pressurized air lines, LNG or gasoline tank systems. Fits perfectly for other technical gases such as Atzetylene, Ammonia, Carbondioxide.

Dimensions/Weight

|

Size (DN) |

Dimensions (mm) |

Kvs Value |

Weight (kg) |

||

| L | H | h | |||

| 15 | 130 | 310 | 90 | 8,0 | 10,5 |

| 20 | 150 | 11,0 | 10,5 | ||

| 25 | 160 | 12,0 | 12,0 | ||

| 32 | 180 | 330 | 120 | 12,0 | 14,5 |

| 40 | 200 | 114,0 | 15,5 | ||

| 50 | 230 | 435 | 130 | 63,0 | 28,5 |

| 65 | 290 | 465 | 155 | 92,0 | 37,0 |

| 80 | 310 | 630 | 180 | 113,0 | 56,5 |

| 100 | 350 | 655 | 150,0 | 69,0 | |

| 125 | 400 | 660 | 210 | 196,0 | 120,0 |

| 150 | 480 | 680 | 235 | 321,0 | 183,0 |

| 200 | 600 | 740 | 285 | 483,0 | 358,0 |

| PN16 | PN25 | |

| Max. design pressure (MPa) PMA | 1,6 | 2,5 |

| Max. design temperature (℃) TMA | 350 | 350 |

| Max. operating pressure (MPa) PMO | 1,6 | 2,5 |

| Max. operating temperature (℃) TMO | 350 | 350 |

| PN | Temperature ℃ | ||||||

| -10・・・+50 | 100 | 150 | 200 | 250 | 300 | 350 | |

| Pressure MPa | |||||||

| PN16 | 1,6 | 1,6 | 1,6 | 1,5 | 1,4 | 1,3 | 1,1 |

| PN25 | 2,5 | 2,5 | 2,4 | 2,3 | 2,2 | 2,0 | 1,8 |

|

Secondary pressure range |

DN15-DN40 | DN50 | DN65 | DN80 | DN100 | DN125-DN200 |

| MPa | Spring number per size | |||||

| < 0,05 | On request | On request | ||||

| 0,05-0,1 | 9 | 28 | 27 | 38 | 37 | |

| 0,1-0,16 | 8 | 27 | 26 | 37 | 36 | |

| 0,16-0,25 | 7 | 26 | 25 | 36 | 35 | |

| 0,25-0,4 | 6 | 25 | 24 | 35 | 34 | |

| 0,4-0,63 | 5 | 24 | 23 | 34 | 33 | |

| 0,63-1,0 | 4 | 23 | 22 | 33 | 32 | |

| 1,0-1,6 | 3 | 22 | 21 | 32 | 32 | |

| > 1,6 | On request | |||||

Secondary pressure ranges higher than 1,6 MPa and lower than 0,05 MPa on request available.

A minimum differential pressure of 0,05 MPa is required.

* Membership registration is required to download the documents.