Direct Acting for steam

Pressure Reducing Valves Direct Acting for steam

REC1

Built-in screen

Features/Applications

Features

Self acting pressure reducing valve for steam

Automatic valve that reduces the steam supply pressure to a defined set pressure.

Pressure fluctuations on upstream side are followed by the downstream side.

No external energy requiredOperating features of direct acting pressure reducing valves

Downstream pressure changes are detected in the detection chamber, and the degree of opening of the valve is directly adjusted to maintain the set pressure.

Compact and cost effective design

Can be installed in tight spaces thanks to its compact design (small/lightweight). Offers reliable operation, energy saving, and productivity improvement.

Superb durability

Most of the materials are made from stainless steel, making it durable and corrosion-resistant.

Easy handling

Pressure can be easily adjusted by the topside handle.

Typical applications

Suitable for F&B equipment, medical equipment, bio-related equipment, and other compact steam equipments.

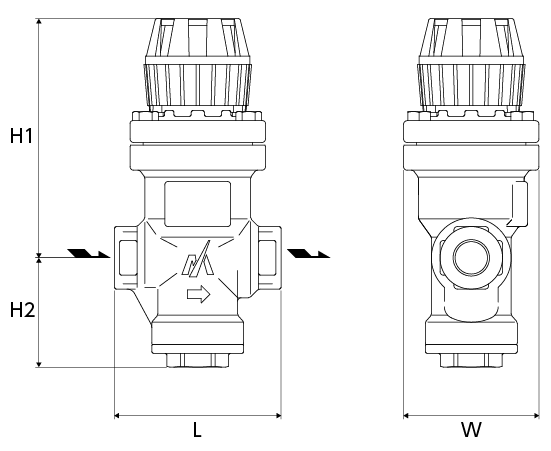

Dimensions/Weight

Dimensions/Weight

Screwed

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| 1/2” | 96 | 138 | 63 | 78 | 3.8 | 5.4 | 2.5 | 3.1 | 2,9 | 6.4 |

| 3/4” | 2,8 | 6.2 | ||||||||

| 1” | ||||||||||

Flanged

| Size | Dimensions (mm) | Dimensions (in) | Weight (kg) | Weight (lb) | ||||||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | JIS(FF,RF) | ASME/JPI(RF) | JIS(FF,RF) | ASME/JPI(RF) | |||||

| 10K,16K | 20K | 150lb | 300lb | 10K,16K | 20K | 150lb | 300lb | |||||||||

| 1/2” | 150 | 138 | 63 | 78 | 5.9 | 5.4 | 2.5 | 3.1 | 4,2 | 4,4 | 3,9 | 4,3 | 9.3 | 9.7 | 8.6 | 9.5 |

| 3/4” | 4,5 | 4,7 | 4,3 | 5,3 | 9.9 | 10.4 | 9.5 | 11.7 | ||||||||

| 1” | 160 | 6.3 | 5,7 | 6,1 | 5,1 | 6,1 | 12.6 | 13.5 | 11.3 | 13.5 | ||||||

Specifications

| Model | Connection |

Max. operating pressure |

operating pressure range |

Control pressure range |

Max. pressure reduction ratio |

Max.operating temperature |

Body material |

|||||

| Type | Size | (MPa) | (psig) |

Primary side pressure (MPa) |

Primary side pressure (psig) |

Secondary side pressure (MPa) |

Secondary side pressure (psig) |

(℃) | (℉) | |||

| REC1-2 |

Screwed Rc, Rp, NPT |

1/2” | 1,6 | 230 | 0,2 - 1,6 | 29 - 230 | 0,02 - 0,2 | 2.9 - 29 | 30:1 | 220 | 428 |

Stainless steel SCS14/CF8M |

| 3/4” | ||||||||||||

| 1” | ||||||||||||

| REC1-6 | 1/2” | 0,2 - 1,6 |

29 - 230 |

0,18 - 0,6 | 26 - 87 | 8.9:1 | ||||||

| 3/4” | ||||||||||||

| 1” | ||||||||||||

| REC1-10 | 1/2” | 0,6 - 1,6 | 87 - 230 | 0,54 - 1,0 | 78 - 145 | 3:1 | ||||||

| 3/4” | ||||||||||||

| 1” | ||||||||||||

| REC1-2F |

Flanged (FF,RF) |

1/2” | 0,2 - 1,6 | 29 - 230 | 0,02 - 0,2 | 2.9 - 29 | 30:1 | |||||

| 3/4” | ||||||||||||

| 1” | ||||||||||||

| REC1-6F | 1/2” | 0,2 - 1,6 | 29 - 230 | 0,18 - 0,6 | 26 - 87 | 8.9:1 | ||||||

| 3/4” | ||||||||||||

| 1” | ||||||||||||

| REC1-10F | 1/2” | 0,6 - 1,6 | 87 - 230 | 0,54 - 1,0 | 78.- 145 | 3:1 | ||||||

| 3/4” | ||||||||||||

| 1” | ||||||||||||

● Minimum differential pressure: 10% of the primary side

● Minimum adjustable flow rate: 3 to 30kg/h (6.6 to 66 lb/h)

● Lockup pressure: Up to 0,03MPa (4.4psig)

● Offset

Up to 60% of the secondary side when secondary side pressure is 0,1MPa (14.5psig) or lower

Up to 0,07MPa (10.2psig) when secondary side pressure exceeds 0,1MPa (14.5psig) but is less than 0,6MPa (87psig)

Up to 0,1MPa (14.5psig) when secondary side pressure is 0,6MPa (87psig)

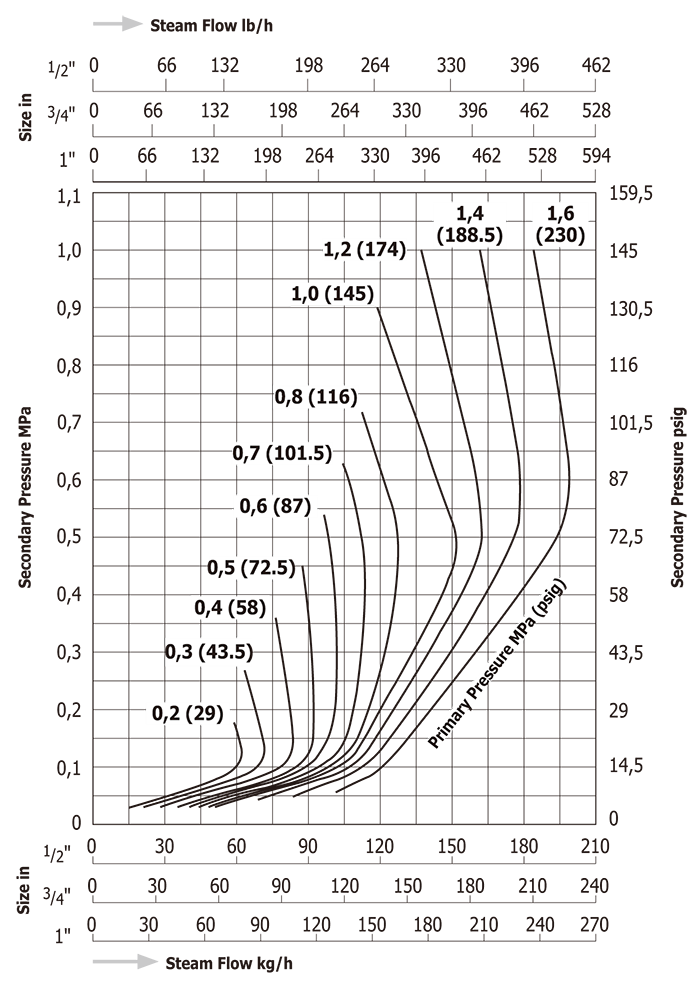

Capacity Chart

● How to use selection chart (example)

To reduce the pressure of 100kg/h (220lb/h) of steam from 1,0MPa to 0,5MPa (145psig to 73psig)

1. Find the point at which the primary side pressure 1,0MPa (145psig) curve and secondary side pressure 0,5MPa (73psig) horizontal line intersect.

2. Trace a vertical line from the point where they intersect, and look for the smallest-sized product where the steam flow rate is 100kg/h (220lb/h) or more at the point where the vertical line you have traced intersects the horizontal size lines.

3. In this case, the REC1-6(F) pressure reducing valve with a size of 15A (1/2”) is optimum.

Download

* Membership registration is required to download the documents.

Features

Self acting pressure reducing valve for steam

Automatic valve that reduces the steam supply pressure to a defined set pressure.

Pressure fluctuations on upstream side are followed by the downstream side.

No external energy requiredOperating features of direct acting pressure reducing valves

Downstream pressure changes are detected in the detection chamber, and the degree of opening of the valve is directly adjusted to maintain the set pressure.

Compact and cost effective design

Can be installed in tight spaces thanks to its compact design (small/lightweight). Offers reliable operation, energy saving, and productivity improvement.

Superb durability

Most of the materials are made from stainless steel, making it durable and corrosion-resistant.

Easy handling

Pressure can be easily adjusted by the topside handle.

Typical applications

Suitable for F&B equipment, medical equipment, bio-related equipment, and other compact steam equipments.

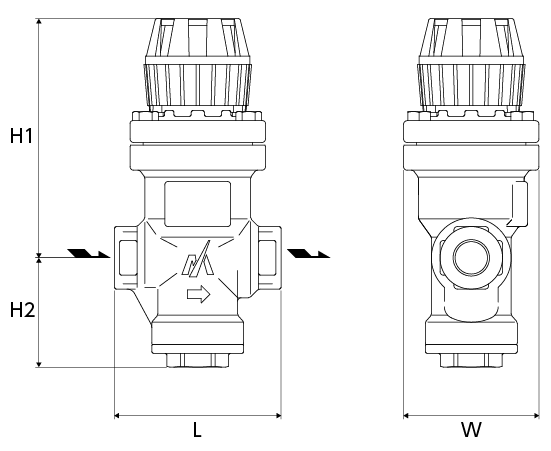

Dimensions/Weight

Screwed

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| 1/2” | 96 | 138 | 63 | 78 | 3.8 | 5.4 | 2.5 | 3.1 | 2,9 | 6.4 |

| 3/4” | 2,8 | 6.2 | ||||||||

| 1” | ||||||||||

Flanged

| Size | Dimensions (mm) | Dimensions (in) | Weight (kg) | Weight (lb) | ||||||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | JIS(FF,RF) | ASME/JPI(RF) | JIS(FF,RF) | ASME/JPI(RF) | |||||

| 10K,16K | 20K | 150lb | 300lb | 10K,16K | 20K | 150lb | 300lb | |||||||||

| 1/2” | 150 | 138 | 63 | 78 | 5.9 | 5.4 | 2.5 | 3.1 | 4,2 | 4,4 | 3,9 | 4,3 | 9.3 | 9.7 | 8.6 | 9.5 |

| 3/4” | 4,5 | 4,7 | 4,3 | 5,3 | 9.9 | 10.4 | 9.5 | 11.7 | ||||||||

| 1” | 160 | 6.3 | 5,7 | 6,1 | 5,1 | 6,1 | 12.6 | 13.5 | 11.3 | 13.5 | ||||||

| Model | Connection |

Max. operating pressure |

operating pressure range |

Control pressure range |

Max. pressure reduction ratio |

Max.operating temperature |

Body material |

|||||

| Type | Size | (MPa) | (psig) |

Primary side pressure (MPa) |

Primary side pressure (psig) |

Secondary side pressure (MPa) |

Secondary side pressure (psig) |

(℃) | (℉) | |||

| REC1-2 |

Screwed Rc, Rp, NPT |

1/2” | 1,6 | 230 | 0,2 - 1,6 | 29 - 230 | 0,02 - 0,2 | 2.9 - 29 | 30:1 | 220 | 428 |

Stainless steel SCS14/CF8M |

| 3/4” | ||||||||||||

| 1” | ||||||||||||

| REC1-6 | 1/2” | 0,2 - 1,6 |

29 - 230 |

0,18 - 0,6 | 26 - 87 | 8.9:1 | ||||||

| 3/4” | ||||||||||||

| 1” | ||||||||||||

| REC1-10 | 1/2” | 0,6 - 1,6 | 87 - 230 | 0,54 - 1,0 | 78 - 145 | 3:1 | ||||||

| 3/4” | ||||||||||||

| 1” | ||||||||||||

| REC1-2F |

Flanged (FF,RF) |

1/2” | 0,2 - 1,6 | 29 - 230 | 0,02 - 0,2 | 2.9 - 29 | 30:1 | |||||

| 3/4” | ||||||||||||

| 1” | ||||||||||||

| REC1-6F | 1/2” | 0,2 - 1,6 | 29 - 230 | 0,18 - 0,6 | 26 - 87 | 8.9:1 | ||||||

| 3/4” | ||||||||||||

| 1” | ||||||||||||

| REC1-10F | 1/2” | 0,6 - 1,6 | 87 - 230 | 0,54 - 1,0 | 78.- 145 | 3:1 | ||||||

| 3/4” | ||||||||||||

| 1” | ||||||||||||

● Minimum differential pressure: 10% of the primary side

● Minimum adjustable flow rate: 3 to 30kg/h (6.6 to 66 lb/h)

● Lockup pressure: Up to 0,03MPa (4.4psig)

● Offset

Up to 60% of the secondary side when secondary side pressure is 0,1MPa (14.5psig) or lower

Up to 0,07MPa (10.2psig) when secondary side pressure exceeds 0,1MPa (14.5psig) but is less than 0,6MPa (87psig)

Up to 0,1MPa (14.5psig) when secondary side pressure is 0,6MPa (87psig)

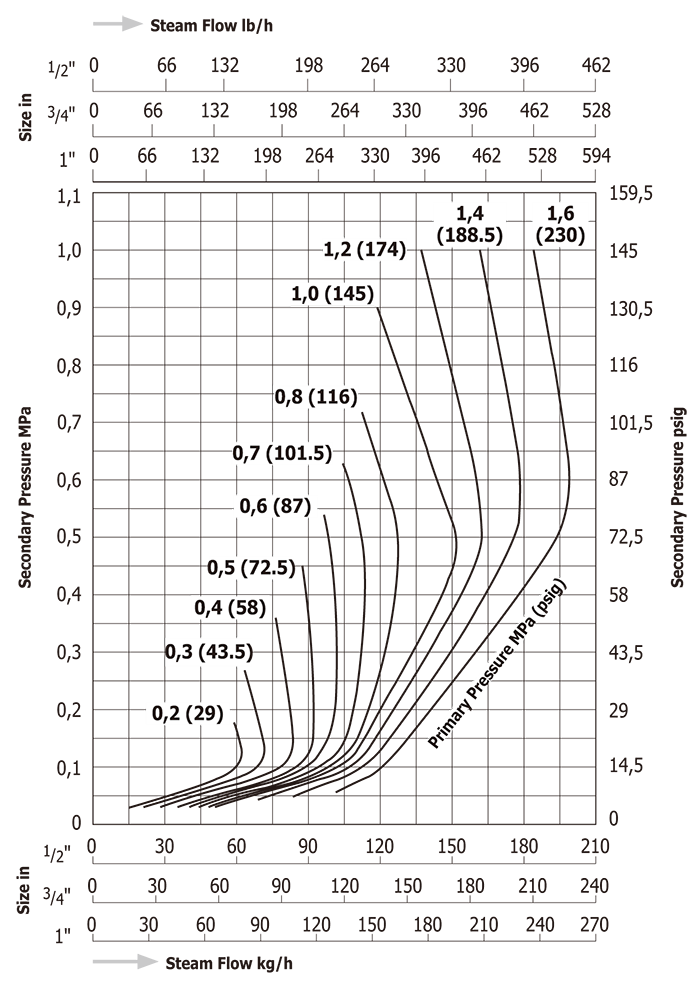

● How to use selection chart (example)

To reduce the pressure of 100kg/h (220lb/h) of steam from 1,0MPa to 0,5MPa (145psig to 73psig)

1. Find the point at which the primary side pressure 1,0MPa (145psig) curve and secondary side pressure 0,5MPa (73psig) horizontal line intersect.

2. Trace a vertical line from the point where they intersect, and look for the smallest-sized product where the steam flow rate is 100kg/h (220lb/h) or more at the point where the vertical line you have traced intersects the horizontal size lines.

3. In this case, the REC1-6(F) pressure reducing valve with a size of 15A (1/2”) is optimum.

* Membership registration is required to download the documents.