Series E | Inverted Bucket Steam Traps

Steam Traps Series E | Inverted Bucket Steam Traps

ES5

1978 Received the Award for Excellence in Energy Saving

Features/Applications

Features

No condensate logging on primary side

Intermittent or continuous discharge depending on condensate loads means no condensate stacking up on the primary side.

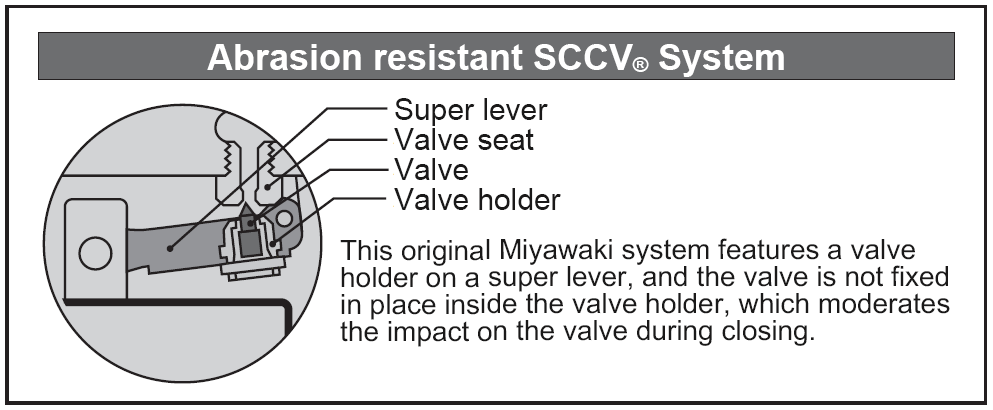

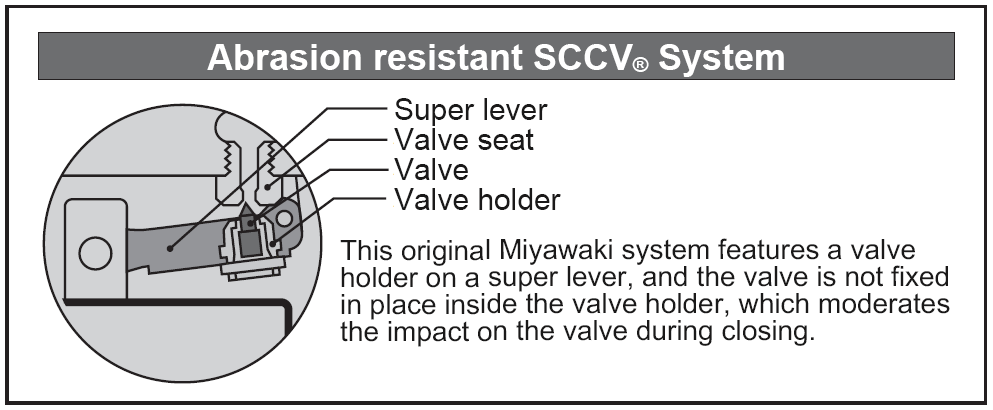

Superb durability

Offers superb durability thanks to the SCCV System valve and robust super lever, as well as stainless steel internal components.

Easy maintenance

For quick and easy maintenance, this model can be repaired directly in line.

Condensate recovery

With its high degree of back pressure tolerance, this model supports condensate recovery at pressures up to 90% of the upstream pressure.

Complete steam containment

A double steam separation mechanism (implemented with a U-shaped duct and inverted bucket) provides reliable steam separation and ensures trap tightness.

Free from steam and air locking

This model is free from steam and air locking due to a small air vent hole in the top of the bucket (discharges hot air and non-condensable gases).

*’SCCV System’ is an abbreviation of Self Closing and Centering Valve System.

Typical applications

-

ES5

-

Extremely small and lightweight, suitable for air conditioning equipment and devices, cleaning devices, dyeing devices, and similar applications.

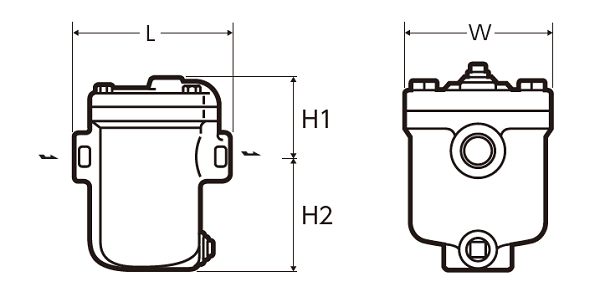

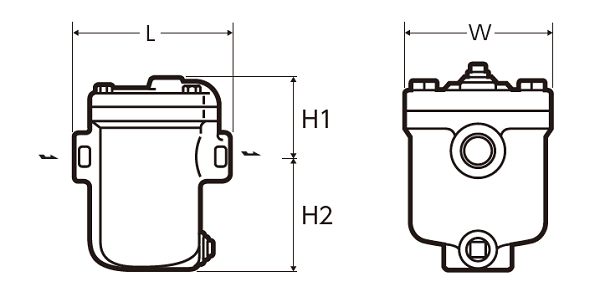

Dimensions/Weight

Dimensions/Weight

| Size (”) | Dimensions (mm) | Dimensions (in) | Weight (kg) |

Weight (lb) |

||||||

| L | H1 | H2 | W | L | H1 | H2 | W | |||

| 1/2” | 103 | 59 | 67 | 75 | 4.1 | 2.3 | 2.6 | 2.95 | 1,9 | 4.2 |

| 3/4” | 105 | 57 | 69 | 4.1 | 2.2 | 2.7 | 2,0 | 4.4 | ||

| 1” | 109 | 4.3 | 2,1 | 4.6 | ||||||

*For ES5 flanged version or custom face-to-face dimensions are available on request.

Specifications

| Model | Connection |

Max. operating pressure |

Max. operating pressure differential |

Max. operating temperature |

Body material | ||||

| Type | Size | (MPa) | (psig) | (MPa) | (psig) | (℃) | (℉) | ||

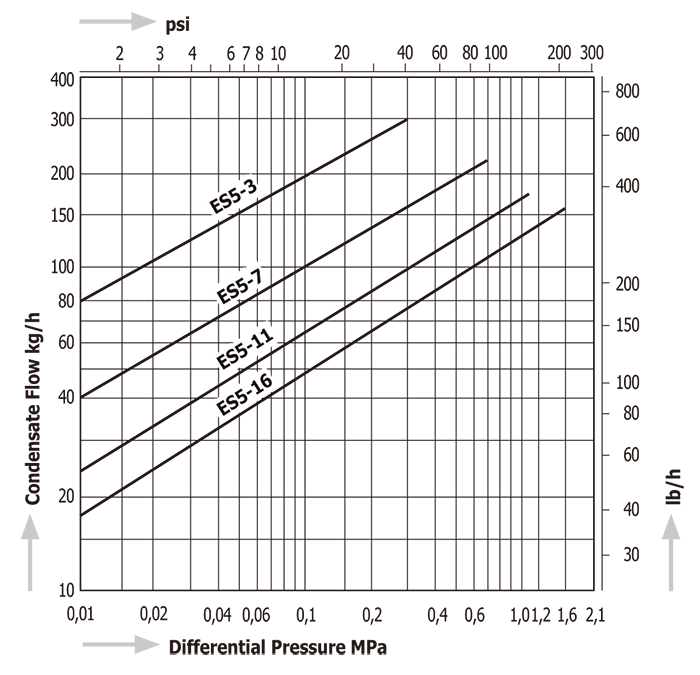

| ES5-3 | Screwed Rc,NPT |

1/2” | 0,3 | 43 | 0,3 | 44 | 350 | 662 | Ductile cast iron FCD450 |

| 3/4” | |||||||||

| 1” | |||||||||

| ES5-7 | 1/2” | 0,7 | 100 | 0,7 | 102 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

| ES5-11 | 1/2” | 1,1 | 160 | 1,1 | 160 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

| ES5-16 | 1/2” | 1,6 | 230 | 1,6 | 232 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

*For ES5 flanged version or custom face-to-face dimensions are available on request.

*Please contact MIYAWAKI to inquire further options.

●Maximum allowable pressure (PMA): 1,6 MPa (230psig) PMA is the pressure that can be tolerated by pressure-resistant parts (body).

●Maximum allowable temperature (TMA): 350℃ (662℉) TMA is the temperature that can be tolerated by pressure-resistant parts (body).

●Minimum operating differential pressure (⊿PMN): 0,01MPa (1.5psig) ⊿PMN is the minimum operating differential pressure between the trap inlet and outlet.

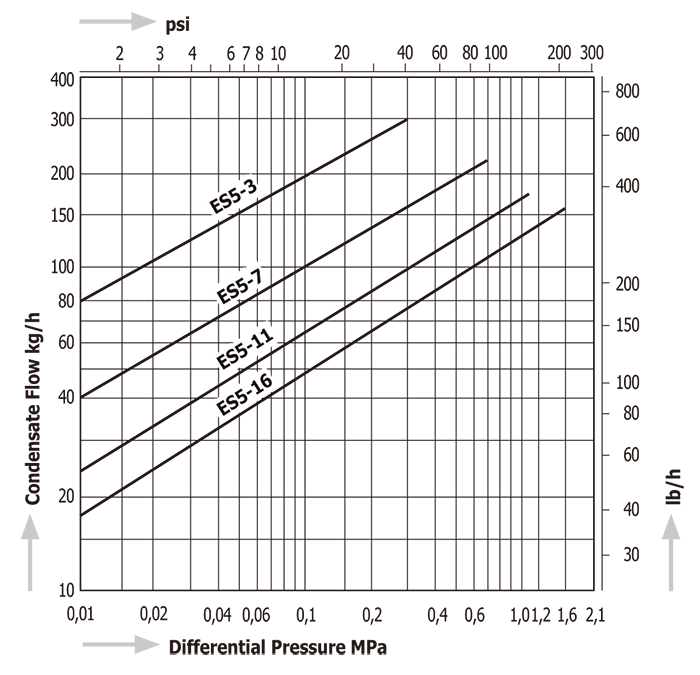

Discharge Capacity

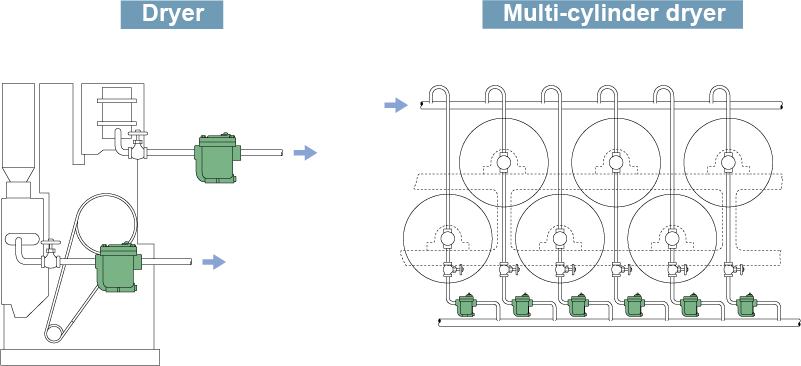

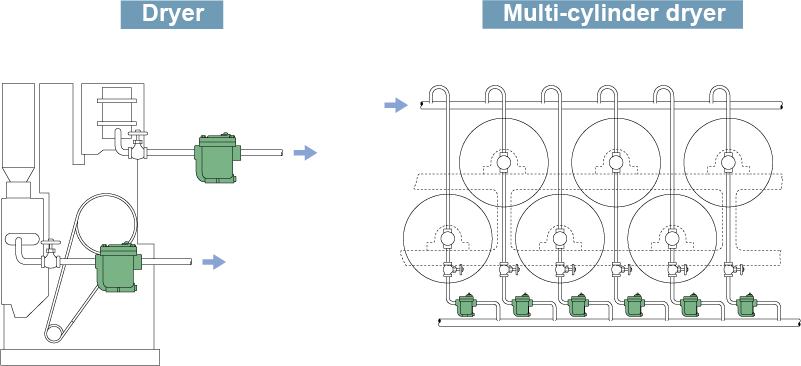

Installation Examples

●To keep the drawing simple, bypass lines, valves, and other required equipment are not displayed.

●If you wish to recover condensate, attach a check valve (CV model) and shut off valve on the trap’s outlet side.

Download

* Membership registration is required to download the documents.

Features

No condensate logging on primary side

Intermittent or continuous discharge depending on condensate loads means no condensate stacking up on the primary side.

Superb durability

Offers superb durability thanks to the SCCV System valve and robust super lever, as well as stainless steel internal components.

Easy maintenance

For quick and easy maintenance, this model can be repaired directly in line.

Condensate recovery

With its high degree of back pressure tolerance, this model supports condensate recovery at pressures up to 90% of the upstream pressure.

Complete steam containment

A double steam separation mechanism (implemented with a U-shaped duct and inverted bucket) provides reliable steam separation and ensures trap tightness.

Free from steam and air locking

This model is free from steam and air locking due to a small air vent hole in the top of the bucket (discharges hot air and non-condensable gases).

*’SCCV System’ is an abbreviation of Self Closing and Centering Valve System.

Typical applications

-

ES5

-

Extremely small and lightweight, suitable for air conditioning equipment and devices, cleaning devices, dyeing devices, and similar applications.

Dimensions/Weight

| Size (”) | Dimensions (mm) | Dimensions (in) | Weight (kg) |

Weight (lb) |

||||||

| L | H1 | H2 | W | L | H1 | H2 | W | |||

| 1/2” | 103 | 59 | 67 | 75 | 4.1 | 2.3 | 2.6 | 2.95 | 1,9 | 4.2 |

| 3/4” | 105 | 57 | 69 | 4.1 | 2.2 | 2.7 | 2,0 | 4.4 | ||

| 1” | 109 | 4.3 | 2,1 | 4.6 | ||||||

*For ES5 flanged version or custom face-to-face dimensions are available on request.

| Model | Connection |

Max. operating pressure |

Max. operating pressure differential |

Max. operating temperature |

Body material | ||||

| Type | Size | (MPa) | (psig) | (MPa) | (psig) | (℃) | (℉) | ||

| ES5-3 | Screwed Rc,NPT |

1/2” | 0,3 | 43 | 0,3 | 44 | 350 | 662 | Ductile cast iron FCD450 |

| 3/4” | |||||||||

| 1” | |||||||||

| ES5-7 | 1/2” | 0,7 | 100 | 0,7 | 102 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

| ES5-11 | 1/2” | 1,1 | 160 | 1,1 | 160 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

| ES5-16 | 1/2” | 1,6 | 230 | 1,6 | 232 | ||||

| 3/4” | |||||||||

| 1” | |||||||||

*For ES5 flanged version or custom face-to-face dimensions are available on request.

*Please contact MIYAWAKI to inquire further options.

●Maximum allowable pressure (PMA): 1,6 MPa (230psig) PMA is the pressure that can be tolerated by pressure-resistant parts (body).

●Maximum allowable temperature (TMA): 350℃ (662℉) TMA is the temperature that can be tolerated by pressure-resistant parts (body).

●Minimum operating differential pressure (⊿PMN): 0,01MPa (1.5psig) ⊿PMN is the minimum operating differential pressure between the trap inlet and outlet.

●To keep the drawing simple, bypass lines, valves, and other required equipment are not displayed.

●If you wish to recover condensate, attach a check valve (CV model) and shut off valve on the trap’s outlet side.

* Membership registration is required to download the documents.