Series G | Ball Float Steam Traps

Steam Traps Series G | Ball Float Steam Traps

G15N

Features/Applications

Features

No condensate logging on primary side (continuous discharge float system)

The floating mechanism discharges condensate immediately at saturation temperature, preventing condensate stacking up on the primary side. Ideally installed in applications where condensate logging cannot be accepted.

Compact with high discharge capacity

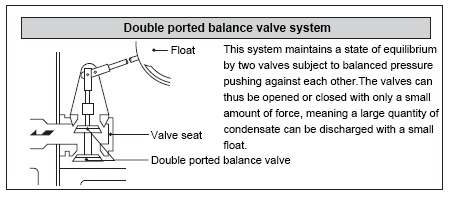

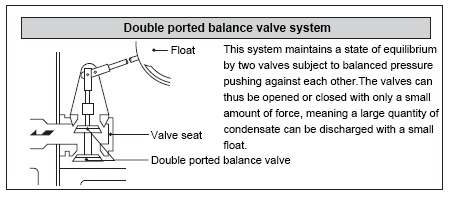

A double ported (duplex) balance valve provides a large discharge capacity in a compact unit. Conically shaped provides this valve maximum sealing with high capacity service.

Easy maintenance

For quick and easy maintenance, this model can be repaired directly in line.

Condensate recovery

With its high degree of back pressure tolerance, this model supports condensate recovery.

Free from steam and air locking

A quick start up is guaranteed, thanks to a diaphragm air vent. The air vent follows the saturation temperature and prevents air and steam locking.

Typical applications

Suitable for various process applications including large-scale heat exchangers in multiple industries, such as industrial plants, F&B process equipment, dyeing/cleaning devices, and air conditioning.

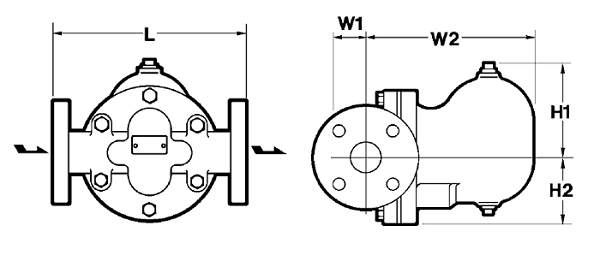

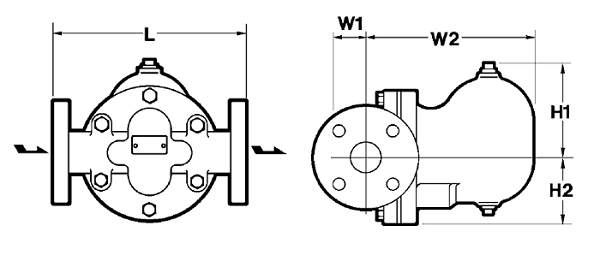

Dimensions/Weight

Dimensions/Weight

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||||

| L | H1 | H2 | W1 | W2 | L | H1 | H2 | W1 | W2 | (kg) | (lb) | |

| 1 1/4” | 300 | 130 | 90 | 30 | 230 | 11.8 | 5.1 | 3.5 | 1.2 | 9.1 | 20,0 | 44.0 |

| 1 1/2” | ||||||||||||

| 2” | ||||||||||||

Specifications

| Model | Connection |

Max. Operating pressure |

Max. operating differential pressure |

Max. operating temperature |

Body material | ||||

| Type | Size | PMO (MPa) | PMO (psig) | ⊿PMX (MPa) | ⊿PMX (psig) | TMO (℃) | TMO (℉) | ||

| G15N-5 | Flanged FF,RF* |

1 1/4” | 0,5 | 73 | 0,5 | 73 | 220 | 428 |

Cast iron FC250 |

| 1 1/2” | |||||||||

| 2” | |||||||||

| G15N-13 | 1 1/4” | 1,3 | 189 | 1,3 | 189 | ||||

| 1 1/2” | |||||||||

| 2” | |||||||||

*Available flange standards: ASME/JPI 150lb, 300lb, DIN PN16, JIS 10K, 16K (ASME/JPI 300lb not available for 2”)

●PMA: 1,6MPa (230psig), TMA: 220℃ (428℉)

●Minimum operating differential pressure (⊿PMN): 0,01MPa (1.5psig) ⊿PMN is the minimum operating differential pressure between the trap inlet and outlet.

●This product uses a double ported balance valve system so if the actual condensate volume is significantly lower than the product’s discharge capacity, there may be a steam leak.

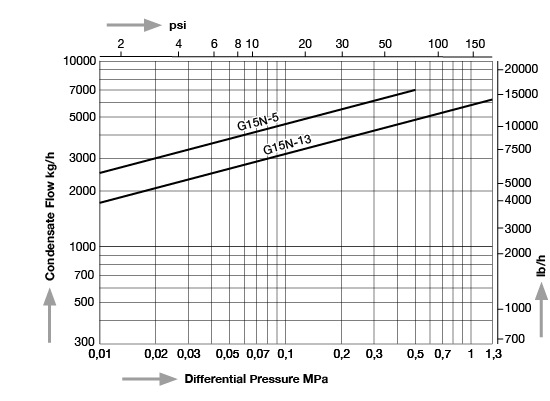

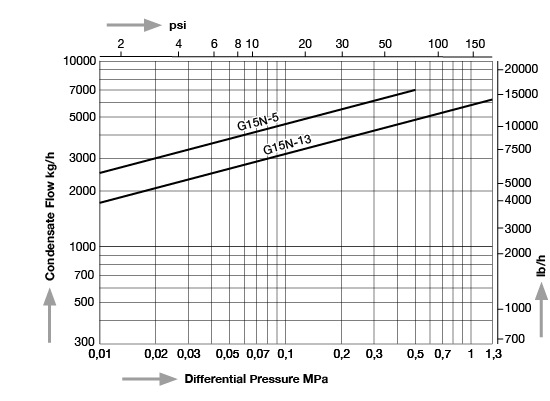

Discharge Capacity

Download

* Membership registration is required to download the documents.

Features

No condensate logging on primary side (continuous discharge float system)

The floating mechanism discharges condensate immediately at saturation temperature, preventing condensate stacking up on the primary side. Ideally installed in applications where condensate logging cannot be accepted.

Compact with high discharge capacity

A double ported (duplex) balance valve provides a large discharge capacity in a compact unit. Conically shaped provides this valve maximum sealing with high capacity service.

Easy maintenance

For quick and easy maintenance, this model can be repaired directly in line.

Condensate recovery

With its high degree of back pressure tolerance, this model supports condensate recovery.

Free from steam and air locking

A quick start up is guaranteed, thanks to a diaphragm air vent. The air vent follows the saturation temperature and prevents air and steam locking.

Typical applications

Suitable for various process applications including large-scale heat exchangers in multiple industries, such as industrial plants, F&B process equipment, dyeing/cleaning devices, and air conditioning.

Dimensions/Weight

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||||

| L | H1 | H2 | W1 | W2 | L | H1 | H2 | W1 | W2 | (kg) | (lb) | |

| 1 1/4” | 300 | 130 | 90 | 30 | 230 | 11.8 | 5.1 | 3.5 | 1.2 | 9.1 | 20,0 | 44.0 |

| 1 1/2” | ||||||||||||

| 2” | ||||||||||||

| Model | Connection |

Max. Operating pressure |

Max. operating differential pressure |

Max. operating temperature |

Body material | ||||

| Type | Size | PMO (MPa) | PMO (psig) | ⊿PMX (MPa) | ⊿PMX (psig) | TMO (℃) | TMO (℉) | ||

| G15N-5 | Flanged FF,RF* |

1 1/4” | 0,5 | 73 | 0,5 | 73 | 220 | 428 |

Cast iron FC250 |

| 1 1/2” | |||||||||

| 2” | |||||||||

| G15N-13 | 1 1/4” | 1,3 | 189 | 1,3 | 189 | ||||

| 1 1/2” | |||||||||

| 2” | |||||||||

*Available flange standards: ASME/JPI 150lb, 300lb, DIN PN16, JIS 10K, 16K (ASME/JPI 300lb not available for 2”)

●PMA: 1,6MPa (230psig), TMA: 220℃ (428℉)

●Minimum operating differential pressure (⊿PMN): 0,01MPa (1.5psig) ⊿PMN is the minimum operating differential pressure between the trap inlet and outlet.

●This product uses a double ported balance valve system so if the actual condensate volume is significantly lower than the product’s discharge capacity, there may be a steam leak.

* Membership registration is required to download the documents.