Series S | Thermodynamic Disc Steam Traps

Steam Traps Series S | Thermodynamic Disc Steam Traps

SU2H

High pressure specification, Dedicated to steam main lines

Features/Applications

Features

Flexible installation

This product can be installed either horizontally or vertically.

Superb durability

The body of the product is made from stainless steel, making it durable and corrosion-resistant, even in aggressive media.

Auto blow off and air vent

Thanks to a bimetal ring, the trap smoothly discharges initial air and cold condensate. (Auto blow-off mechanism)

Tailored design

Manufacturing with custom face-to-face dimensions is possible.

Typical applications

Dedicated to steam main lines

Dimensions/Weight

Dimensions/Weight

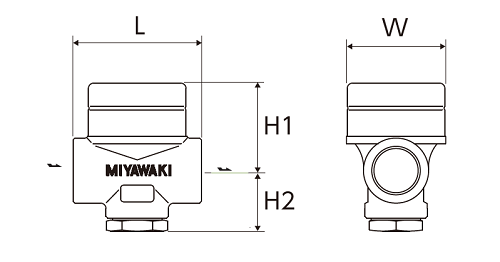

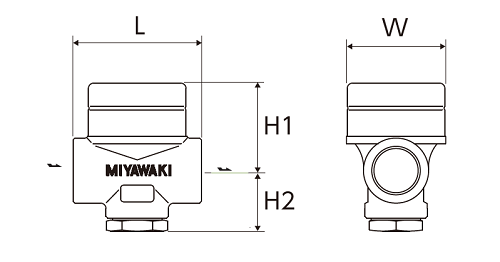

Screwed

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| 1/2” | 70 | 47 | 32 | 53 | 2.8 | 1.9 | 1.3 | 2.1 | 0,8 | 1.8 |

| 3/4” | ||||||||||

| 1” | 75 | 51 | 3.0 | 2.0 | 1,0 | 2.2 | ||||

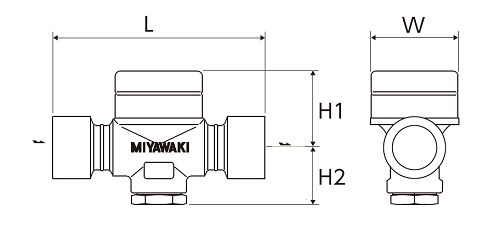

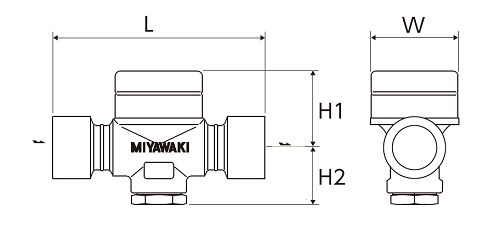

Socket Weld

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| 1/2” | 140 | 47 | 32 | 53 | 5.51 | 1.85 | 1.26 | 2.09 | 1,5 | 3.3 |

| 3/4” | 1,4 | 3.1 | ||||||||

| 1” | 1,3 | 2.9 | ||||||||

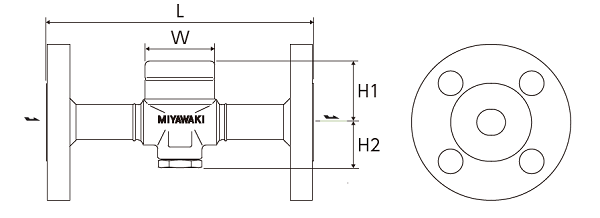

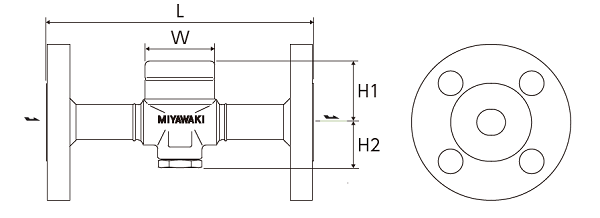

Flanged

| Size | Dimensions (mm) | Dimensions (in) | Weight (kg) | Weight (lb) | ||||||||||||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | JIS(FF,RF) | ASME/JPI(RF) | JIS(FF,RF) | ASME/JPI(RF) | |||||||||||

| 20K | 30K | 40K | 63K | 300lb | 600lb | 900lb | 20K | 30K | 40K | 63K | 300lb | 600lb | 900lb | |||||||||

| 1/2” | 205 | 47 | 32 | 53 | 8.07 | 1.85 | 1.26 | 2.09 | 2,6 | 3,8 | 4,1 | 4,9 | 2,7 | 3,3 | 5,7 | 5.7 | 8.4 | 9.0 | 10.8 | 6.0 | 7.3 | 12.6 |

| 3/4” | 3,0 | 4,1 | 4,4 | 6,2 | 3,7 | 4,6 | 7,1 | 6.6 | 9.0 | 9.7 | 13.7 | 8.2 | 10.1 | 15.7 | ||||||||

| 1” | 4,0 | 5,0 | 5,4 | 7,0 | 4,3 | 5,4 | 9,6 | 8.8 | 11.0 | 11.9 | 15.4 | 9.5 | 11.9 | 21.2 | ||||||||

DIN PN40 PN63 PN100

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| DN15 | 150 | 47 | 32 | 53 | 5.9 | 1.9 | 1.3 | 2.1 | 2,6 | 5.7 |

| DN20 | 3,3 | 7.3 | ||||||||

| DN25 | 160 | 6.3 | 3,8 | 8.4 | ||||||

*Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

Specifications

| Model | Connection |

Max. operating pressure |

Max. operating pressure differential |

Max. operating temperature |

Body material |

||||

| Type | Size |

PMO (MPa) |

PMO (psig) |

(MPa) | (psig) |

TMO (℃) |

TMO (℉) |

||

| SU2H |

Screwed Rc,NPT |

1/2” | 6,4 | 928 | 6,4 | 928 | 425 | 800 |

Stainless steel SUS 420J2 |

| 3/4” | |||||||||

| 1” | |||||||||

| SU2HF |

Flanged FF,RF |

1/2” | |||||||

| 3/4” | |||||||||

| 1” | |||||||||

| SU2HW |

Socket Weld SW |

1/2” | |||||||

| 3/4” | |||||||||

| 1” | |||||||||

●SU2HF flange and pipe are carbon steel

●SU2HW welded parts are carbon steel

●Maximum allowable pressure (PMA): 6,4MPa (928psig)

PMA is the pressure that can be tolerated by pressure-resistant parts (body).

●Maximum allowable temperature (TMA): 425℃ (800℉)

TMA is the temperature that can be tolerated by pressure-resistant parts (body).

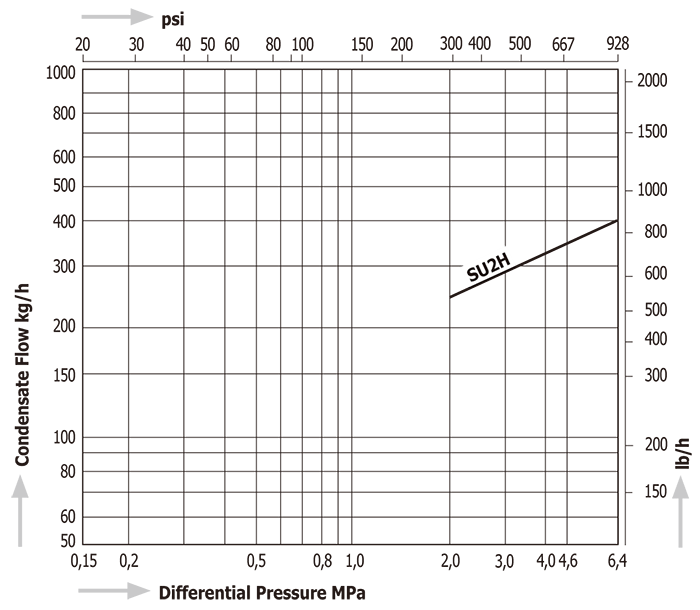

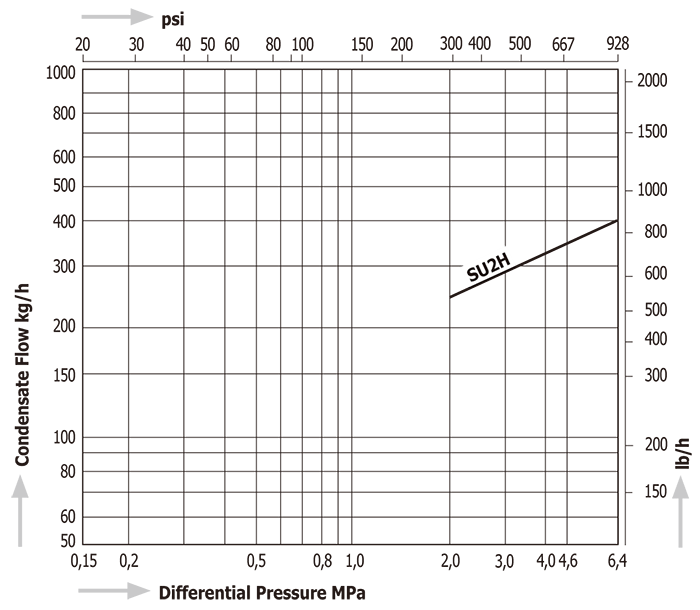

Discharge Capacity

Download

* Membership registration is required to download the documents.

Features

Flexible installation

This product can be installed either horizontally or vertically.

Superb durability

The body of the product is made from stainless steel, making it durable and corrosion-resistant, even in aggressive media.

Auto blow off and air vent

Thanks to a bimetal ring, the trap smoothly discharges initial air and cold condensate. (Auto blow-off mechanism)

Tailored design

Manufacturing with custom face-to-face dimensions is possible.

Typical applications

Dedicated to steam main lines

Dimensions/Weight

Screwed

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| 1/2” | 70 | 47 | 32 | 53 | 2.8 | 1.9 | 1.3 | 2.1 | 0,8 | 1.8 |

| 3/4” | ||||||||||

| 1” | 75 | 51 | 3.0 | 2.0 | 1,0 | 2.2 | ||||

Socket Weld

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| 1/2” | 140 | 47 | 32 | 53 | 5.51 | 1.85 | 1.26 | 2.09 | 1,5 | 3.3 |

| 3/4” | 1,4 | 3.1 | ||||||||

| 1” | 1,3 | 2.9 | ||||||||

Flanged

| Size | Dimensions (mm) | Dimensions (in) | Weight (kg) | Weight (lb) | ||||||||||||||||||

| L | H1 | H2 | W | L | H1 | H2 | W | JIS(FF,RF) | ASME/JPI(RF) | JIS(FF,RF) | ASME/JPI(RF) | |||||||||||

| 20K | 30K | 40K | 63K | 300lb | 600lb | 900lb | 20K | 30K | 40K | 63K | 300lb | 600lb | 900lb | |||||||||

| 1/2” | 205 | 47 | 32 | 53 | 8.07 | 1.85 | 1.26 | 2.09 | 2,6 | 3,8 | 4,1 | 4,9 | 2,7 | 3,3 | 5,7 | 5.7 | 8.4 | 9.0 | 10.8 | 6.0 | 7.3 | 12.6 |

| 3/4” | 3,0 | 4,1 | 4,4 | 6,2 | 3,7 | 4,6 | 7,1 | 6.6 | 9.0 | 9.7 | 13.7 | 8.2 | 10.1 | 15.7 | ||||||||

| 1” | 4,0 | 5,0 | 5,4 | 7,0 | 4,3 | 5,4 | 9,6 | 8.8 | 11.0 | 11.9 | 15.4 | 9.5 | 11.9 | 21.2 | ||||||||

DIN PN40 PN63 PN100

| Size | Dimensions (mm) | Dimensions (in) | Weight | |||||||

| L | H1 | H2 | W | L | H1 | H2 | W | (kg) | (lb) | |

| DN15 | 150 | 47 | 32 | 53 | 5.9 | 1.9 | 1.3 | 2.1 | 2,6 | 5.7 |

| DN20 | 3,3 | 7.3 | ||||||||

| DN25 | 160 | 6.3 | 3,8 | 8.4 | ||||||

*Customized face-to-face dimensions on request.

*Please contact MIYAWAKI for further information.

| Model | Connection |

Max. operating pressure |

Max. operating pressure differential |

Max. operating temperature |

Body material |

||||

| Type | Size |

PMO (MPa) |

PMO (psig) |

(MPa) | (psig) |

TMO (℃) |

TMO (℉) |

||

| SU2H |

Screwed Rc,NPT |

1/2” | 6,4 | 928 | 6,4 | 928 | 425 | 800 |

Stainless steel SUS 420J2 |

| 3/4” | |||||||||

| 1” | |||||||||

| SU2HF |

Flanged FF,RF |

1/2” | |||||||

| 3/4” | |||||||||

| 1” | |||||||||

| SU2HW |

Socket Weld SW |

1/2” | |||||||

| 3/4” | |||||||||

| 1” | |||||||||

●SU2HF flange and pipe are carbon steel

●SU2HW welded parts are carbon steel

●Maximum allowable pressure (PMA): 6,4MPa (928psig)

PMA is the pressure that can be tolerated by pressure-resistant parts (body).

●Maximum allowable temperature (TMA): 425℃ (800℉)

TMA is the temperature that can be tolerated by pressure-resistant parts (body).

* Membership registration is required to download the documents.