-

Precautions for Installing Steam Traps

-

Piping on the Secondary Side of Steam Traps

-

When laying steam trap condensate discharge lines, first keep the following in mind.

-

● The length of the line should be as short as possible to reduce resistance.

-

● Form a gradient of around 1:200 (10cm lower per 20m) to encourage smooth condensate flow.

Additionally, this is based on the fact that the aperture of the condensate discharge line is the same as that of steam trap.

By the way, when determining the size of the condensate discharge lines, as already mentioned in relation to the steam trap back pressure, it is necessary to consider back pressure by flash steam. This is important to consider when selecting a steam trap, depending on the relationship between the required capacity of the steam trap and expected back pressure due to flash steam, it could be that the size of the condensate discharge line needs to be larger than the diameter of the steam trap.

The following are some important points to note when laying condensate discharge lines.

-

Connecting to shared condensate discharge lines

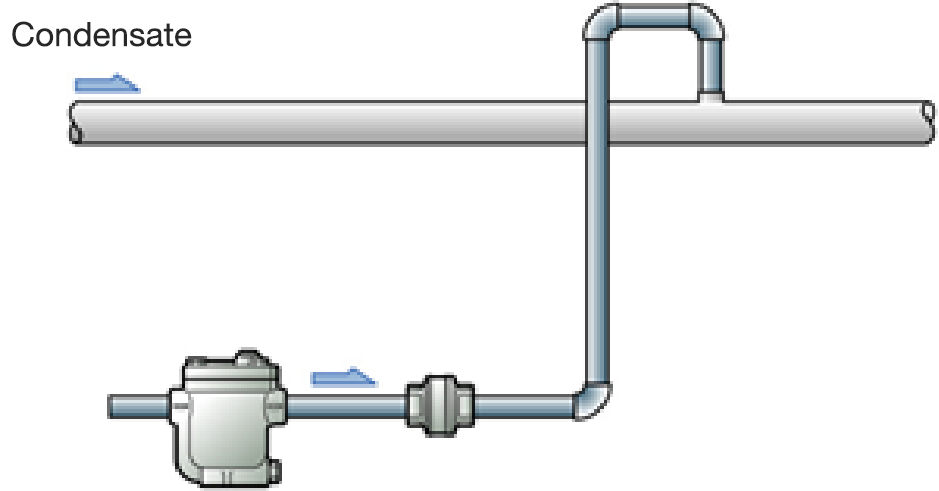

When a condensate discharge line is connected to a shared condensate discharged line, it should be connected to the top of the shared condensate discharged line, rather than the bottom of it. (Figure 4.10) This manner of connection allows the condensate flow to the shared condensate discharged line to remain flow smoothly, and prevents condensate from flowing to the outlet of the steam trap. The check valve should be installed at the outlet of the steam trap.

Figure 4.10 Connection to shared condensate discharge line

-

Discharging to the drain

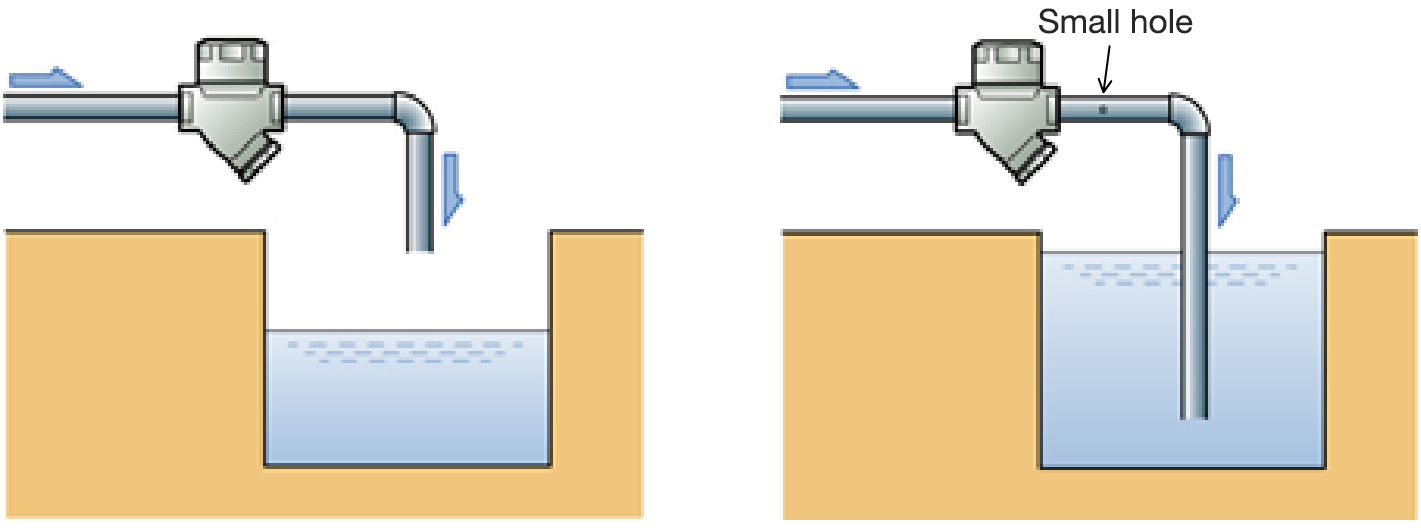

When the condensate discharging line leads to the drain, the head of the discharging line should not be submerged. (Left side of figure 4.11)

We occasionally see cases in which the head of the line is submerged to prevent scattering of flash steam generated by trap operation noise and condensate. There is a possibility that dirty water from the drain will flow back into the steam piping or heating unit when it is in a vacuum state, such as during shutdown.

If water is likely to rise causing submergence during rain, it is wise to provide a small hole in the discharge line. (Right side of figure 4.11)

Figure 4.11