-

Steam Trap Selection

-

Precautions when deciding condensate discharge capacity

-

The condensate discharging capacity of steam traps is unambiguously determined by pressure differences at its inlet and outlet. It can be confirmed by the flow rate table of each steam trap provided by the manufacturer. However, the operating pressure of equipment fluctuates repeatedly, except for very small load fluctuations.

Therefore, mentioned in the previous section "Inlet pressure of steam traps",it is necessary to decide not only the operations pressure, but also the pressure variation of each equipment when determining the condensate charge capacity of steam traps.

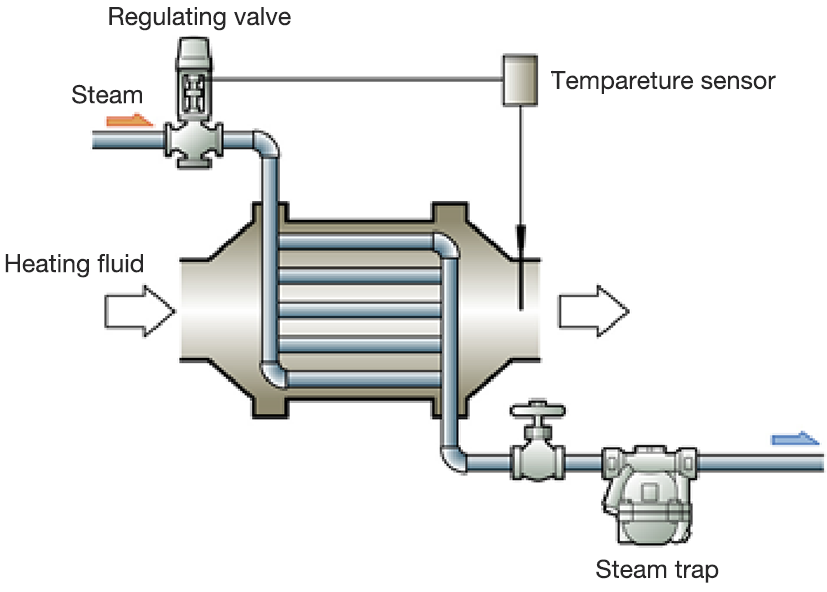

Figure 3.7,the valve adjusts its opening angle according to the outlet temperature of the heated material in the heat transfer device, and adjusts the amount of supplied steam, to keep the outlet temperature constant.

When the amount of steam is decreased by closing the regulating valve, the pressure in the heat transfer device is also reduced. And the condensate discharge capacity is also reduced. At this time, if the condensate cannot be discharged fully and remains in the heat transfer device, the heat transfer area is substantially reduced. As the result, the temperature of the heated material decreases, the opening degree of the regulating valve increases, and the amount of supplied steam also increases. The pressure in the heat transfer device also increases, as does the condensate discharge capacity, and so the condensate is fully discharged. When the outlet temperature of the heat transfer device is increased, the regulating valve is squeezed shut again. This repetition causes delays in temperature control due to the performance limits of detection sensitivity in the temperature sensor, and the response speed of the regulatory valve, making it unstable in some cases.

To avoid such problems, it is necessary to grasp the actual minimum operating pressure of the equipment. Further, if particularly strict temperature control is required, a steam trap with sufficient capacity for the pressure must be selected.

Ball float steam traps or bucket traps are suitable for these types of equipment because these steam traps discharge condensate immediately.

Figure 3.7 Steam Heating Exchanger